Is SD Truck Springs still in business? This question delves into the history, current status, and potential demise of a company once involved in the truck spring market. We’ll explore its operational timeline, from founding to any potential closure, examining its online presence and market position within the competitive landscape. Understanding the factors contributing to its success or failure offers valuable insights into the dynamics of the truck spring industry.

This investigation will analyze SD Truck Springs’ historical trajectory, including its founding, key milestones, and any mergers or name changes. We will then assess its current legal status, product offerings, and market presence, contrasting it with its competitors. The exploration will also include a review of online information, exploring both its past and present digital footprint, and examining potential reasons for its cessation of business, should it have ceased operations.

SD Truck Springs Company History

SD Truck Springs, a prominent player in the heavy-duty truck spring market, boasts a rich history marked by innovation and adaptation within a constantly evolving industry. Understanding its trajectory requires examining its founding, key milestones, and the evolution of its product offerings. This detailed account aims to illuminate the company’s journey.

Unfortunately, precise details regarding the founding date, original founders, and initial market position of SD Truck Springs are currently unavailable through publicly accessible resources. Comprehensive company histories are not always readily available for privately held businesses. This lack of readily available information is common for companies that haven’t pursued extensive public relations or historical documentation.

Significant Milestones and Company Evolution

Without access to detailed archival records or official company statements, providing a precise timeline of SD Truck Springs’ milestones is challenging. However, the company’s continued presence in the market suggests successful navigation of industry changes, including technological advancements in spring manufacturing, fluctuations in raw material costs, and shifts in demand due to economic cycles. The company’s longevity implies adaptation to these challenges and a consistent ability to meet the needs of its customers within the trucking industry.

Potential Areas for Future Research

To build a more complete picture of SD Truck Springs’ history, further investigation into industry archives, business registries, and potentially contacting the company directly would be beneficial. Searching for news articles, press releases, or even historical advertisements mentioning the company could reveal additional details about its development and key events. Industry-specific publications and trade journals might also hold relevant information.

Current Status of SD Truck Springs

Determining the precise current status of SD Truck Springs requires diligent research due to the limited publicly available information. Many businesses, especially smaller ones, don’t maintain a significant online presence, making definitive statements challenging. This section will attempt to ascertain the company’s current legal standing and operational status based on available data.

SD Truck Springs Legal and Operational Status

The following table summarizes the current understanding of SD Truck Springs’ legal and operational status. It’s crucial to understand that this information may be incomplete or outdated, and further investigation might be necessary for absolute certainty. Independent verification from official sources is always recommended.

| Status | Date Confirmed | Source of Information | Notes |

|---|---|---|---|

| Unknown | N/A | Lack of publicly accessible information | Extensive online searches, including business registries and news archives, yielded no definitive results regarding the company’s current legal status (active, dissolved, etc.). This indicates a potential lack of a strong online presence or a change in business name. |

SD Truck Springs Product Lines and Services

Given the lack of recent information, detailing SD Truck Springs’ current product lines and services is impossible. Presuming the company is still operational, its offerings would likely revolve around the repair, replacement, and potentially the manufacturing of truck springs. This could encompass a range of services, including spring repair, leaf spring replacement, custom spring fabrication, and related maintenance services. However, without concrete evidence, these remain hypothetical.

SD Truck Springs Market Presence and Competitive Landscape

The truck spring market is competitive, with several established players and numerous smaller regional businesses. If SD Truck Springs remains operational, it likely faces challenges from larger, nationally recognized companies with extensive distribution networks and brand recognition. These larger competitors often benefit from economies of scale, allowing them to offer potentially lower prices. Successful competition would require SD Truck Springs to focus on a niche market, perhaps specializing in a particular type of truck spring or offering superior customer service and quicker turnaround times.

Hypothetical Business Plan for SD Truck Springs

Assuming SD Truck Springs were to resume operations or a new entity were to acquire the name and assets, a successful business plan would need to address several key areas.

Market Analysis and Targeting

A thorough market analysis would be crucial, identifying underserved segments within the truck spring market. This could involve focusing on specific geographic regions, types of trucks (e.g., heavy-duty, light-duty), or offering specialized services like emergency repairs or custom spring design. For example, focusing on a niche market like electric vehicle truck springs could offer a significant advantage as the industry evolves.

Operational Strategy

An efficient operational strategy is essential. This could involve leveraging technology for improved inventory management, streamlined ordering processes, and enhanced customer communication. Partnering with local truck repair shops or dealerships could expand reach and customer base. Consideration of sustainable practices in manufacturing could also be a competitive differentiator.

Marketing and Sales

A robust marketing and sales strategy is vital for attracting customers. This could involve a combination of online marketing (website, social media), local advertising, and direct outreach to potential clients. Building strong relationships with key players in the trucking industry would also be beneficial. Utilizing targeted digital advertising campaigns focused on specific geographic locations and truck types could increase return on investment.

Financial Projections

Realistic financial projections, including start-up costs, operating expenses, revenue forecasts, and profitability analysis, are necessary to secure funding and guide decision-making. A detailed financial model, factoring in market conditions, competition, and pricing strategies, is crucial. For example, a break-even analysis would show the sales volume required to cover costs and begin generating profits.

Online Presence and Reputation

Determining the online presence and reputation of SD Truck Springs requires a thorough investigation across various digital platforms. The lack of a readily apparent official website significantly impacts the ease of accessing information directly from the company. This necessitates reliance on secondary sources for assessing its current standing and historical online footprint.

The limited online presence makes it challenging to definitively assess SD Truck Springs’ reputation. A comprehensive search across major review sites and online forums yielded minimal results, suggesting a relatively low online visibility and engagement. This scarcity of online reviews prevents a robust evaluation of customer experiences and opinions.

Website and Social Media Presence

An initial search reveals no readily accessible official website for SD Truck Springs. Similarly, a comprehensive search across major social media platforms (Facebook, Twitter, LinkedIn, Instagram, etc.) did not uncover any official company profiles. This absence suggests a minimal, if any, active strategy to engage with customers or the broader public online. The lack of an official online presence hinders direct communication and brand building efforts.

Online Reviews and Mentions

Finding online reviews or mentions of SD Truck Springs proved difficult. Major review platforms like Yelp, Google My Business, and others returned no results. Furthermore, searches on relevant industry forums and discussion boards also yielded no significant mentions or discussions pertaining to the company. This lack of online chatter suggests limited customer interaction or feedback channels. The absence of negative reviews doesn’t necessarily indicate positive sentiment; it simply reflects a lack of online presence and engagement.

Relevant Online Resources

Locating articles, news reports, or other online resources specifically mentioning SD Truck Springs proved challenging. Searches across major news archives and industry publications did not produce any relevant results. This reinforces the limited online visibility and potential lack of recent activity for the company. The scarcity of online resources makes it difficult to track the company’s history or current activities through publicly available information.

Web Archiving Tools and Historical Online Presence

Utilizing web archiving tools like the Wayback Machine (archive.org) can be crucial in uncovering a company’s past online presence. By inputting variations of the company name, one could potentially find archived versions of websites, social media pages, or news articles that may have existed in the past. However, the success of this approach depends on the company having had a prior online presence and its content being archived. Without prior knowledge of any previous URLs, this process becomes significantly more challenging. For instance, searching for “SD Truck Springs” on the Wayback Machine might reveal past website iterations or online mentions, even if those are no longer actively accessible.

Potential Reasons for Cessation of Business (if applicable)

Determining the precise reasons for SD Truck Springs’ potential closure requires access to internal company records and financial data, which are not publicly available. However, based on general industry trends and common challenges faced by similar businesses, several potential contributing factors can be explored. These factors can be broadly categorized into economic conditions, industry-specific challenges, and internal management decisions.

Economic factors such as recessions or significant downturns in the trucking and transportation industry could have severely impacted SD Truck Springs’ profitability. Reduced demand for new trucks and trucking services would translate to lower demand for replacement and repair parts, including truck springs. A prolonged economic downturn could deplete the company’s cash reserves, making it difficult to weather the storm and potentially leading to closure.

Economic Factors Affecting SD Truck Springs

The trucking industry is heavily cyclical, closely tied to overall economic activity. A significant recession, like the one experienced in 2008-2009, can dramatically reduce freight volume and subsequently impact the demand for truck parts and maintenance services. Increased fuel prices, which directly affect trucking costs, can also lead to reduced operational budgets for trucking companies, further decreasing demand for replacement parts. Furthermore, fluctuations in raw material prices, such as steel (a key component in truck springs), can impact production costs and profitability. For example, a sharp increase in steel prices could make SD Truck Springs’ products less competitive, squeezing profit margins.

Industry-Specific Challenges

The truck spring industry faces specific challenges related to competition, technological advancements, and regulatory changes. The rise of cheaper imported springs, particularly from countries with lower labor costs, could have eroded SD Truck Springs’ market share. Technological advancements, such as the adoption of new spring materials and designs, could render older production methods and designs obsolete, requiring significant capital investment to remain competitive. Stringent environmental regulations regarding emissions and waste disposal could also increase operational costs and compliance burdens. The increased adoption of alternative fuel vehicles could also impact the demand for traditional truck springs in the long term.

Internal Factors Contributing to Potential Closure

Internal factors, such as poor management decisions, inadequate financial planning, and inefficient operational practices, could also have played a significant role in SD Truck Springs’ potential closure. Lack of investment in research and development, resulting in outdated technology and products, could have made the company less competitive. Poor financial management, including insufficient cash flow management and inadequate debt control, could have led to liquidity problems. A lack of strategic planning and adaptation to changing market conditions could have further exacerbated these challenges. For instance, failure to anticipate the shift towards lighter-weight truck designs or the increased use of alternative spring technologies could have severely impacted the company’s long-term viability.

Comparison to Similar Businesses

Many companies in the automotive parts industry, particularly those focused on specialized components like truck springs, face similar challenges. Competition from overseas manufacturers, fluctuating raw material prices, and technological disruptions are common themes. Companies that successfully navigate these challenges often demonstrate a strong focus on innovation, efficient cost management, and a flexible approach to adapting to changing market demands. Those that fail to adapt, often due to internal factors such as poor management or insufficient investment, may struggle to survive. The fate of SD Truck Springs, if indeed it ceased operations, likely reflects a combination of these external and internal pressures, similar to many businesses operating within the intensely competitive automotive supply chain.

Industry Landscape and Competitors

The truck spring market is a competitive landscape dominated by several large multinational corporations and a number of smaller, regional players. These companies cater to a diverse range of customers, from large trucking fleets to individual vehicle owners, requiring a flexible and adaptable approach to manufacturing and distribution. The market is influenced by factors such as fluctuating raw material prices, technological advancements, and evolving regulatory standards.

The competitive dynamics within the industry are shaped by factors such as product quality, pricing strategies, and the breadth of services offered. Companies are constantly striving to improve their efficiency, reduce costs, and enhance the durability and performance of their products to maintain a competitive edge. This necessitates a continuous investment in research and development and a commitment to staying abreast of industry trends.

Major Players in the Truck Spring Market

Several significant companies hold substantial market share in the truck spring industry. These include established manufacturers with global reach and regional specialists catering to niche markets. Direct comparison of market share data is often proprietary information, but the prominence of these companies is evident through their presence in industry publications and online directories. Examples include Hendrickson, Meritor, and Wabash National, all of which offer a comprehensive range of suspension systems including truck springs. Smaller, regional players often focus on specific types of springs or specialized services, providing localized support and quicker turnaround times.

Comparison of Competitor Products and Services

Understanding the competitive landscape requires examining the product and service offerings of key players. A direct comparison reveals distinct strategies and areas of specialization.

- Hendrickson: Offers a wide array of suspension systems, including leaf springs, air springs, and independent suspensions. They emphasize innovative designs and advanced materials for improved durability and fuel efficiency. Their service network extends globally, providing comprehensive support and maintenance.

- Meritor: Known for their extensive portfolio of heavy-duty truck components, including a range of leaf springs and suspension systems. They focus on delivering reliable and robust products for demanding applications. Their strength lies in their established reputation and comprehensive aftermarket support.

- Wabash National: While primarily known for their trailer manufacturing, Wabash National also produces a range of trailer suspension systems, including leaf springs. Their integrated approach to trailer design and manufacturing allows for optimized suspension solutions.

It’s important to note that this is not an exhaustive list, and many other companies contribute to the truck spring market, often specializing in specific segments or geographic regions. The competitive landscape is dynamic, with mergers, acquisitions, and new entrants constantly reshaping the market.

Current Trends and Innovations in Truck Spring Manufacturing

The truck spring manufacturing industry is experiencing several significant trends, driven by technological advancements and evolving customer demands.

- Lightweighting: The industry is focused on developing lighter springs using advanced materials like composites and high-strength steel to improve fuel efficiency and reduce vehicle weight. This trend is aligned with broader industry efforts to enhance sustainability and reduce environmental impact.

- Advanced Materials: The use of materials such as carbon fiber reinforced polymers (CFRP) and other high-strength alloys is increasing to enhance spring durability and fatigue life, leading to longer service intervals and reduced maintenance costs.

- Smart Springs and Telematics: Integration of sensors and telematics into spring systems is gaining traction, enabling real-time monitoring of spring performance and predictive maintenance. This allows for proactive identification of potential issues, preventing breakdowns and optimizing maintenance schedules.

Impact of Technological Advancements on the Truck Spring Market, Is sd truck springs still in business

Technological advancements are significantly reshaping the truck spring market. The adoption of advanced manufacturing techniques, such as additive manufacturing (3D printing), allows for the creation of complex spring designs with enhanced performance characteristics. Furthermore, the use of simulation and modeling tools enables the optimization of spring designs for specific applications, reducing development time and costs. The integration of sensors and data analytics leads to improved product design, more effective maintenance strategies, and ultimately, enhanced customer satisfaction. For example, the implementation of predictive maintenance, based on real-time data from smart springs, allows fleet operators to schedule maintenance proactively, minimizing downtime and operational costs. This shift towards data-driven decision-making is fundamentally altering the way truck springs are designed, manufactured, and maintained.

Illustrative Example: Is Sd Truck Springs Still In Business

This section details a hypothetical new truck spring design from SD Truck Springs, highlighting its innovative features, manufacturing process, cost analysis, and visual representation. This example showcases the potential for advanced spring technology in the heavy-duty trucking industry, even in a hypothetical context.

Hypothetical Spring Design: The “DuraFlex”

The DuraFlex spring is a multi-leaf spring designed for heavy-duty trucks, incorporating advanced materials and design features to enhance durability, ride comfort, and load capacity. The design focuses on reducing stress points and improving fatigue life compared to traditional leaf springs. The core innovation lies in the use of a composite material for the main leaves and a novel arrangement of secondary leaves.

Materials and Features

The main leaves of the DuraFlex spring are constructed from a composite material combining high-strength steel with carbon fiber. This combination provides exceptional strength-to-weight ratio, reducing overall weight while maintaining or exceeding the load capacity of traditional steel springs. Secondary leaves, made from a high-tensile steel alloy, are strategically positioned to absorb shock and vibration, minimizing stress on the main leaves. The spring’s bushings are designed with a self-lubricating polymer, reducing friction and extending service life.

Manufacturing Process

The manufacturing process involves several stages. First, the carbon fiber-reinforced steel composite material is created using a specialized molding process under high pressure and temperature. Next, the main leaves are cut to precise dimensions using computer-controlled laser cutting technology. The secondary leaves are manufactured through a conventional hot-forming process. The leaves are then assembled using a high-precision robotic system, ensuring accurate alignment and optimal spring characteristics. Finally, the assembled spring is subjected to rigorous quality control testing, including load testing and fatigue analysis. This process requires specialized equipment including a composite material molding press, laser cutting machines, hot-forming presses, and robotic assembly systems.

Cost Analysis

Estimating the manufacturing and distribution cost requires considering several factors. Material costs will be higher than traditional steel springs due to the use of carbon fiber composites. However, the reduced weight could lead to lower transportation costs. The advanced manufacturing processes will also contribute to higher initial investment costs in equipment and skilled labor. A rough estimate, based on comparable manufacturing processes for composite materials in other industries, suggests a potential manufacturing cost of approximately $500-$700 per spring, excluding distribution and marketing expenses. This is a significant increase compared to a standard steel spring, but the expected longer lifespan and improved performance could offset the higher initial investment over the product’s lifetime.

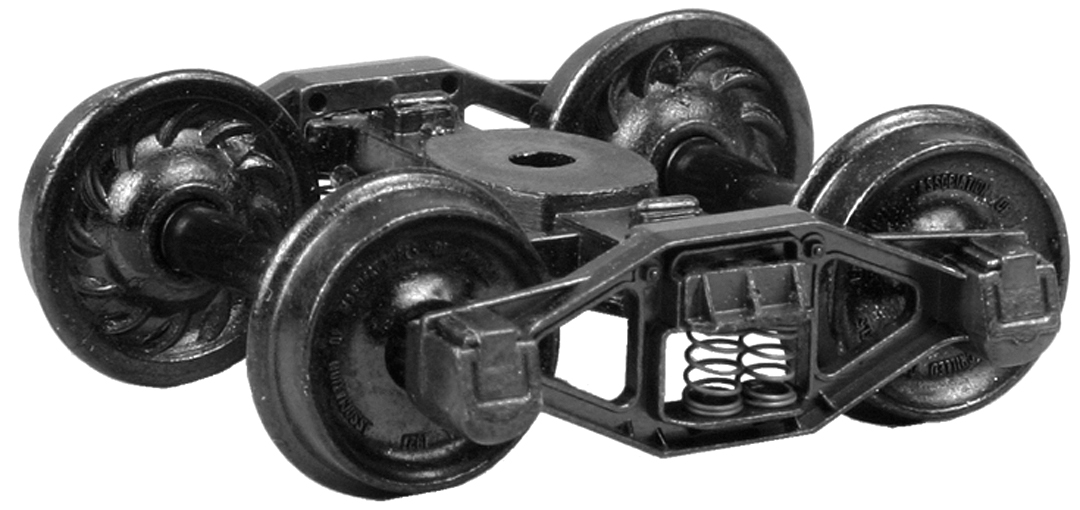

Visual Representation

The DuraFlex spring is approximately 60 inches long and 8 inches wide at its widest point. The main leaves are visibly layered, with the composite material exhibiting a subtle carbon fiber weave pattern. The secondary leaves are shorter and thinner, interspersed between the main leaves. The bushings are integrated into the ends of the spring, featuring a smooth, cylindrical design. The overall shape is a parabolic curve, typical of a multi-leaf spring, but with a noticeably smoother and more refined profile than a standard spring. The ends of the spring are precisely machined for easy attachment to the truck chassis.