How to start a paper cup business? It’s a question brimming with potential, a venture that taps into the ever-present demand for disposable tableware. From market research and securing funding to establishing a robust production line and crafting a compelling brand, launching a successful paper cup business requires careful planning and execution. This guide navigates you through each crucial step, offering insights into the challenges and rewards of entering this dynamic industry.

This comprehensive guide covers everything from initial market analysis and the creation of a solid business plan to efficient production, strategic distribution, and effective marketing techniques. We’ll explore various funding options, examine the legal and regulatory landscape, and delve into the intricacies of financial management to ensure long-term success. By the end, you’ll have a clear roadmap to transform your paper cup business idea into a thriving reality.

Market Research and Analysis

Thorough market research is crucial for launching a successful paper cup business. Understanding your target audience, competitive landscape, and the potential impact of market trends will significantly influence your business strategy and overall success. This section details key aspects of market research relevant to starting a paper cup business.

Key Demographics for Paper Cup Purchases

Three key demographics consistently demonstrate high demand for paper cups: food service businesses (restaurants, cafes, catering companies), event organizers (concerts, conferences, festivals), and educational institutions (schools, universities). Food service businesses require large quantities for daily operations, while event organizers need cups for large gatherings. Educational institutions represent a significant, consistent market due to high student and staff populations. These three groups offer diverse purchasing patterns and volumes, allowing for a strategic approach to market penetration.

Pricing Strategies of Existing Paper Cup Businesses

Analyzing the pricing strategies of established competitors is essential for competitive positioning. Three common approaches include: Cost-plus pricing, where businesses calculate production costs and add a markup for profit; Value-based pricing, which sets prices based on perceived value to the customer, often for premium or eco-friendly products; and Competitive pricing, where businesses match or slightly undercut competitors’ prices. For example, a large-scale manufacturer might use cost-plus pricing to maximize profit margins on high-volume orders, while a smaller, specialized business focusing on sustainable cups might utilize value-based pricing to highlight their unique selling proposition. A regional distributor might use competitive pricing to gain market share.

Advantages and Disadvantages of Eco-Friendly Paper Cups

The increasing consumer awareness of environmental issues presents both advantages and disadvantages for focusing on eco-friendly paper cups. Advantages include attracting environmentally conscious customers willing to pay a premium, improving brand image and reputation, and potentially accessing government grants or subsidies designed to support sustainable businesses. Disadvantages include higher production costs due to the use of recycled or sustainably sourced materials, potentially limiting profit margins and potentially narrower market appeal compared to conventional cups. The increased cost might require a higher selling price, which could impact sales volume. However, the long-term benefits of brand loyalty and positive public perception can outweigh these initial drawbacks.

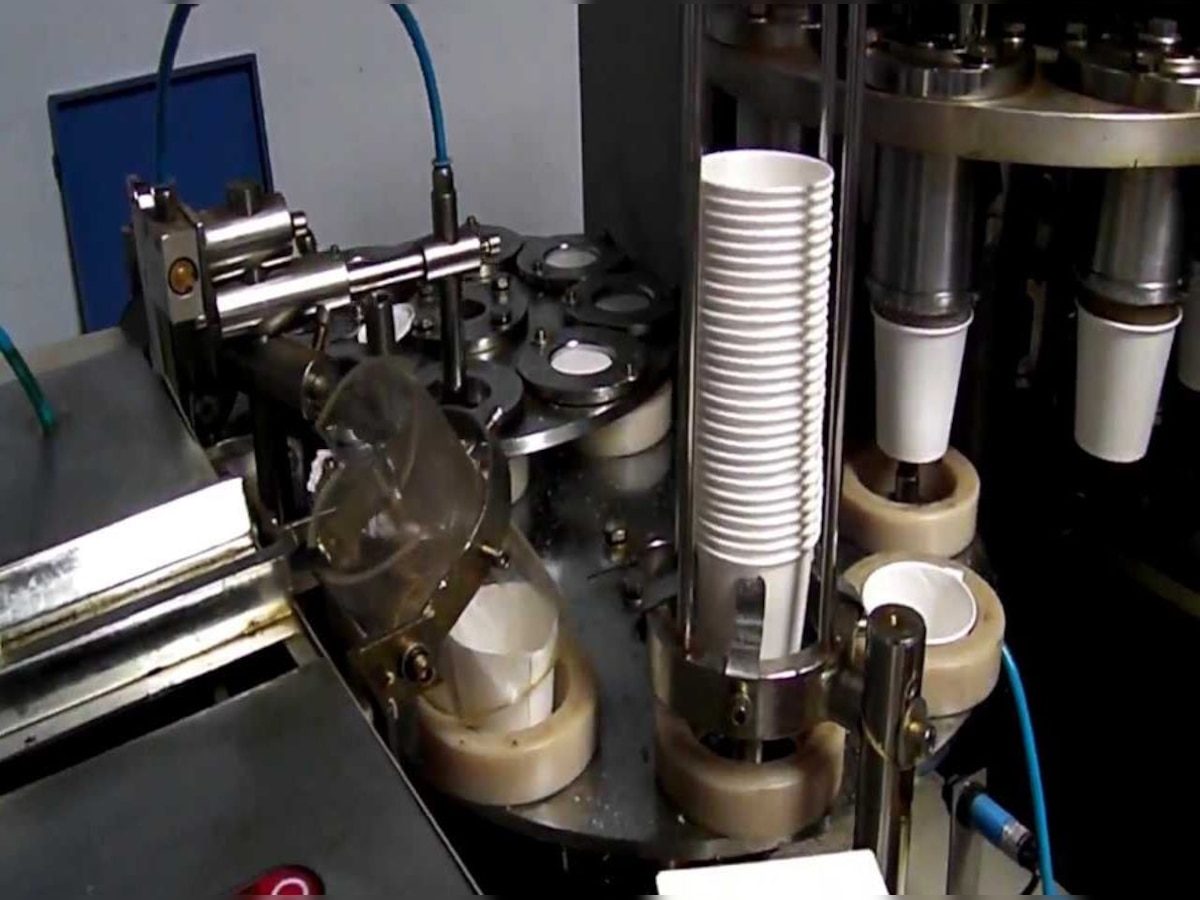

Comparison of Paper Cup Manufacturing Machines

Choosing the right manufacturing machine is crucial for efficiency and profitability. The table below compares features and pricing of different machines, acknowledging that specific prices will vary depending on the manufacturer, model, and features.

| Machine Type | Production Capacity (cups/hour) | Features | Approximate Price Range (USD) |

|---|---|---|---|

| Automatic Paper Cup Machine | 5000-20000 | High-speed production, automated processes, customizable cup sizes | $50,000 – $200,000+ |

| Semi-Automatic Paper Cup Machine | 1000-5000 | More affordable, requires some manual operation, suitable for smaller businesses | $10,000 – $50,000 |

| Manual Paper Cup Machine | <1000 | Lowest initial investment, ideal for very small-scale operations or specialized production | $1,000 – $10,000 |

Business Plan Development

A robust business plan is crucial for securing funding, guiding operations, and ensuring the long-term success of your paper cup business. This plan should detail your startup costs, projected revenue streams, and profit margins, while also outlining a comprehensive marketing strategy and exploring various funding options. A well-defined plan acts as a roadmap, helping you navigate the challenges and capitalize on opportunities within the competitive landscape.

Startup Costs and Projected Revenue

Developing a realistic budget is paramount. Consider costs associated with equipment (e.g., cup-making machinery, printing press if offering customized cups), raw materials (paper, inks, adhesives), facility rental or purchase, permits and licenses, marketing and advertising, and initial inventory. Projected revenue should be based on realistic sales forecasts, taking into account market demand, pricing strategies, and potential sales channels. For example, a small-scale operation producing 10,000 cups per month at an average price of $0.10 per cup would generate $1,000 in monthly revenue. This needs to be balanced against your monthly costs to determine your profit margin. More sophisticated models may use sales projections based on market share assumptions within a specific geographic area.

Marketing Strategy

Reaching your target customers requires a multi-pronged marketing approach. Online strategies could include creating a professional website with e-commerce capabilities, utilizing social media marketing (e.g., targeted ads on Facebook, Instagram), and engaging in search engine optimization () to improve online visibility. Offline marketing could involve direct sales to local businesses, participation in trade shows or industry events, and distributing flyers or brochures in high-traffic areas. Consider partnering with local businesses, such as cafes or restaurants, to supply them with your paper cups. A successful marketing strategy will involve consistent brand messaging and a clear understanding of your target market’s needs and preferences.

Funding Options

Securing sufficient capital is essential for launching your business. Three viable funding options include:

- Self-funding: Using personal savings or investments to bootstrap the business. This provides complete control but may limit initial growth potential.

- Small Business Loans: Obtaining a loan from a bank or credit union. This requires a strong business plan and a good credit history. The Small Business Administration (SBA) offers loan guarantee programs to reduce lender risk.

- Crowdfunding: Utilizing online platforms like Kickstarter or Indiegogo to raise capital from a large number of individuals. This requires a compelling campaign and a strong online presence.

Business Registration and Permits

The process of registering your business and obtaining necessary permits varies by location. Generally, you’ll need to choose a business structure (sole proprietorship, partnership, LLC, etc.), register your business name, and obtain any required licenses and permits related to manufacturing, food safety (if applicable), and environmental regulations. Consult your local government agencies (e.g., the Small Business Administration, your state’s Secretary of State office) for specific requirements and assistance. Thoroughly researching and complying with all regulations is crucial to avoid legal issues and ensure your business operates legally and ethically. Failure to do so can result in significant fines and potential business closure.

Production and Sourcing

Establishing a robust production and sourcing strategy is crucial for the success of your paper cup business. This involves securing reliable suppliers for raw materials, choosing an optimal production location, and determining the appropriate production capacity to meet anticipated demand. Careful planning in these areas will directly impact your profitability and ability to scale your operations.

Potential Paper Cup Material Suppliers

Identifying reliable suppliers for paperboard, inks, and other necessary materials is paramount. The quality and consistency of these materials directly affect the final product’s quality and your production efficiency. Securing competitive pricing is also vital for maintaining profitability. The following are examples of potential suppliers, though specific contact information is subject to change and should be independently verified. This list is not exhaustive, and thorough research is recommended to identify suppliers best suited to your specific needs and location.

- Supplier A: A hypothetical large-scale paperboard manufacturer specializing in food-grade materials. Contact information would typically include a website, phone number, and email address located on their website’s “Contact Us” page. They might offer various paperboard grades and thicknesses, potentially requiring minimum order quantities.

- Supplier B: A regional distributor of packaging materials, offering a range of paperboard options and potentially other related products like lids or coatings. Their contact details could be found through online directories or industry publications.

- Supplier C: A specialized supplier of inks designed for food-safe printing on paper cups. They would likely have a website showcasing their ink types, certifications, and contact information.

- Supplier D: A manufacturer of machinery parts for paper cup production, potentially offering technical support and maintenance services. Their contact details could be obtained via their website or industry trade shows.

- Supplier E: A provider of biodegradable or compostable paper cup materials, catering to environmentally conscious businesses. Their contact information could be found through online searches for sustainable packaging solutions.

Paper Cup Production Facility Location Selection

The choice of location for your production facility significantly impacts operational costs, accessibility to markets, and regulatory compliance. Factors to consider include proximity to raw material suppliers, transportation infrastructure, access to skilled labor, and local regulations concerning manufacturing and waste disposal. A cost-benefit analysis comparing various potential locations is essential.

For example, a location near major transportation hubs could reduce shipping costs, while a site with access to a skilled workforce could lower labor expenses and improve production efficiency. Conversely, locations with stringent environmental regulations might increase operational costs but could enhance the company’s sustainability image. A detailed analysis, including considerations of zoning laws, utility costs, and tax incentives, is necessary to determine the optimal location.

Optimal Production Capacity Calculation

Determining the optimal production capacity requires a careful analysis of projected demand and production capabilities. This involves forecasting future sales, considering production efficiency, and factoring in potential growth. The calculation should ensure sufficient capacity to meet anticipated demand while avoiding overinvestment in equipment and infrastructure.

Production Capacity = (Projected Annual Demand / Number of Production Days) / Production Rate per Day

For example, if your projected annual demand is 1,000,000 cups, you operate 250 days a year, and your production rate is 5,000 cups per day, your required production capacity would be:

(1,000,000 cups / 250 days) / 5,000 cups/day = 8 machines (assuming each machine produces 5000 cups/day)

This calculation provides a starting point and should be adjusted based on factors such as seasonal demand fluctuations, equipment downtime, and potential future growth.

Paper Cup Manufacturing Process Flowchart

The paper cup manufacturing process involves several key steps, from receiving raw materials to packaging the finished product. A well-defined process flow is crucial for efficiency and quality control. The following illustrates a simplified flowchart:

[Descriptive Flowchart]

Imagine a flowchart starting with a rectangle labeled “Raw Materials (Paperboard, Ink, etc.)”. An arrow points to a rectangle “Printing and Cutting”. Another arrow from this rectangle points to “Cup Forming”. A further arrow points to “Lining (if applicable)”. Another arrow points to “Quality Control”. A subsequent arrow points to “Packaging”. Finally, an arrow points to “Finished Product (Paper Cups)”. Each step could have associated sub-processes, but this simplified flowchart represents the main stages. This visual representation aids in understanding the production flow and identifying potential bottlenecks.

Sales and Distribution: How To Start A Paper Cup Business

Successfully launching a paper cup business hinges on a robust sales and distribution strategy. Reaching your target market efficiently and effectively requires careful planning and execution across multiple channels, incorporating smart packaging choices and a competitive pricing model. This section Artikels key considerations for maximizing your sales potential.

Distribution Channels

Selecting the right distribution channels is crucial for reaching your target customer base. A multi-channel approach often yields the best results, balancing reach and cost-effectiveness. Three effective distribution channels for paper cups include wholesale, retail, and online sales. Wholesale involves selling large quantities of cups directly to businesses like restaurants and cafes. Retail distribution involves selling smaller quantities to consumers through stores, supermarkets, or convenience shops. Online sales leverage e-commerce platforms to reach a broader audience, particularly businesses and individuals who prefer online purchasing. Each channel presents unique advantages and disadvantages, requiring a strategic assessment based on your business goals and resources.

Packaging Options and Their Impact

The packaging of your paper cups significantly influences consumer perception and product protection. Several options exist, each with its own benefits and drawbacks. For example, simple bulk packaging, ideal for wholesale clients prioritizing cost-effectiveness, lacks the visual appeal to attract individual consumers. On the other hand, individually wrapped cups, while increasing costs, enhance hygiene and present a more premium image, suitable for retail or online sales. Sustainable packaging options, such as recyclable or compostable materials, are increasingly favored by environmentally conscious consumers, potentially commanding a price premium. The choice depends on your target market, brand image, and cost considerations. For instance, a high-end cafe might favor individually wrapped cups in a stylish design, while a large-scale event planner may prioritize bulk packaging for cost efficiency.

Pricing Strategy

Developing a competitive pricing strategy requires a careful balancing act between production costs, market competition, and desired profit margins. A cost-plus pricing model, where you add a markup to your production costs, provides a simple starting point. However, a more sophisticated approach considers competitor pricing, market demand, and perceived value. For example, premium cups with unique designs or sustainable materials can command higher prices than basic, unbranded cups. Analyzing competitor pricing helps you determine your position in the market—whether to offer competitive pricing, premium pricing, or a value-based pricing strategy focusing on superior quality or sustainability. Regular price adjustments may be necessary based on market conditions and operational efficiency improvements.

Effective Sales Pitches

Effective sales pitches require tailoring your message to the specific needs and priorities of your potential clients. For restaurants and cafes, emphasize cost-effectiveness, consistent quality, and the potential for branding opportunities (custom printed cups). For event planners, highlight the aesthetic appeal, convenience, and suitability for large-scale events. For online sales, focus on the ease of ordering, competitive pricing, and fast delivery options. A strong sales pitch should clearly articulate the value proposition of your paper cups and address the specific pain points of your target audience. For example, a pitch to a restaurant might emphasize reduced labor costs associated with washing reusable cups, while a pitch to an event planner might highlight the seamless integration with event themes and branding.

Branding and Marketing

A strong brand and a well-executed marketing strategy are crucial for success in the competitive paper cup market. Effective branding differentiates your product, builds customer loyalty, and ultimately drives sales. A comprehensive marketing campaign, encompassing both online and offline channels, is essential to reach your target audience and communicate your unique selling proposition.

Logo Design and Brand Identity

Your logo and overall brand identity should visually communicate the core values of your paper cup business. Consider whether you want to project an image of eco-friendliness (using earthy tones and natural imagery), sophistication (employing minimalist design and premium materials), or affordability (utilizing bright colors and playful fonts). The logo should be memorable, versatile (adaptable to various sizes and formats), and reflective of your brand personality. For instance, a company focused on sustainability might incorporate a leaf or tree motif into its logo, while a company targeting high-end cafes might opt for a more refined, minimalist design. The brand identity extends beyond the logo to encompass color palettes, typography, and overall visual style, ensuring consistent brand messaging across all platforms.

Marketing Campaign Development

A successful marketing campaign requires a clear understanding of your target market and a well-defined marketing objective. This might involve building brand awareness among local businesses, targeting specific consumer segments (e.g., event planners, coffee shops), or penetrating a new geographic market. The campaign should leverage a mix of marketing channels, including online advertising (e.g., Google Ads, social media ads), public relations (e.g., press releases, media outreach), and traditional marketing (e.g., brochures, flyers). Consider the budget allocated to the marketing campaign and choose channels that offer the best return on investment. For example, a small business might focus on local marketing efforts, such as sponsoring community events or distributing flyers in high-traffic areas. A larger company with a broader reach might invest in national advertising campaigns.

Social Media Strategy

Social media platforms offer a powerful means to engage with customers, build brand awareness, and promote your paper cups. A comprehensive social media strategy involves identifying the platforms most relevant to your target audience (e.g., Instagram for visually-driven marketing, LinkedIn for B2B outreach), creating engaging content (e.g., high-quality images and videos of your cups, behind-the-scenes glimpses of your production process), and consistently interacting with your followers. Running targeted advertising campaigns on social media can help reach a wider audience and drive traffic to your website or online store. For example, a company selling eco-friendly cups might run Instagram ads targeting environmentally conscious consumers. Regular posting and consistent engagement are key to building a strong online presence and fostering a loyal customer base.

Marketing Materials Examples

Compelling marketing materials are essential for showcasing your paper cups and conveying your brand message effectively. A well-designed website should provide detailed information about your products, your company’s values, and contact information. Brochures and flyers can be used to highlight key features and benefits of your paper cups, potentially including special offers or promotions. High-quality product photography is crucial for showcasing the appearance and quality of your cups. For example, a brochure might feature images of the cups being used in various settings, such as at a coffee shop, at a party, or at a corporate event. The website could include customer testimonials and case studies to build trust and credibility. Consider incorporating interactive elements into your marketing materials, such as QR codes linking to your website or social media pages.

Legal and Regulatory Compliance

Launching a paper cup business requires navigating a complex web of legal and regulatory requirements. Failure to comply can result in hefty fines, business closure, and damage to your brand reputation. Understanding and adhering to these regulations is crucial for long-term success.

Licensing and Permits

Securing the necessary licenses and permits is a fundamental first step. Requirements vary significantly depending on location (city, state, and country). These typically include business licenses, which are generally obtained at the local or state level, and potentially permits related to food safety (if selling cups for food service), manufacturing, and waste disposal. The process usually involves completing applications, providing documentation (such as proof of business registration and insurance), and paying associated fees. For example, in the United States, a business license is usually obtained from the city or county where the business operates, while food handling permits might come from the state’s health department. In many jurisdictions, an environmental permit may also be required if the manufacturing process involves significant waste generation or the use of certain chemicals. It’s crucial to contact your local regulatory bodies early in the planning stages to determine the exact requirements and timelines for obtaining all necessary documentation.

Environmental Regulations

Environmental compliance is paramount, focusing primarily on waste management and sustainable practices. Paper cup manufacturing generates waste in the form of paper scraps, ink residue, and potentially other byproducts depending on the production process. Regulations often dictate how this waste must be handled, including proper sorting, recycling, and disposal in accordance with local and national environmental protection laws. For instance, some regions may mandate specific recycling programs or limit the disposal of certain types of waste in landfills. Furthermore, the use of sustainable materials and manufacturing processes is becoming increasingly important, with some regions implementing regulations or incentives promoting the use of recycled paper or biodegradable materials. Failure to comply can result in significant penalties and reputational damage. Proactive engagement with environmental agencies to understand and implement best practices is vital.

Product Safety and Quality Control

Ensuring product safety and quality is essential for maintaining consumer trust and avoiding legal issues. This involves establishing robust quality control procedures throughout the production process, from raw material sourcing to finished product packaging. This might include regular inspections of raw materials, testing for harmful substances (like heavy metals in inks), and quality checks at various stages of production. Relevant standards and certifications, such as those set by the FDA (Food and Drug Administration) in the US or equivalent bodies in other countries, should be considered to guarantee compliance with safety regulations regarding food contact materials. Documentation of these processes is crucial for demonstrating compliance during audits or in the event of any legal challenges. Implementing a comprehensive quality management system (QMS) based on established standards like ISO 9001 can be beneficial in ensuring consistent quality and safety.

Financial Management and Projections

Successful operation of a paper cup business requires meticulous financial planning and management. A robust financial forecast, coupled with effective tracking and management strategies, is crucial for ensuring profitability and long-term sustainability. This section Artikels key aspects of financial management, including forecasting, metric tracking, cash flow management, and profit reinvestment strategies.

Financial Forecasting for the First Three Years

Creating a detailed financial forecast involves projecting revenue, expenses, and profit over a three-year period. This projection should be based on realistic market analysis, sales projections, and cost estimates. For example, a startup might project sales of 10,000 cups in the first year, increasing to 25,000 in the second year, and 50,000 in the third, based on anticipated market growth and marketing efforts. Corresponding cost projections for materials, labor, and overhead would then be developed, leading to a projected profit margin for each year. This forecast should include a sensitivity analysis to assess the impact of potential variations in sales volume, material costs, or other key factors. Consider using spreadsheet software like Excel or Google Sheets to build an interactive financial model.

Key Financial Metric Tracking

Regular tracking of key financial metrics is vital for monitoring performance and making informed business decisions. These metrics include sales revenue, cost of goods sold (COGS), gross profit margin, operating expenses, net profit margin, and inventory levels. Sales data can be tracked daily or weekly using point-of-sale (POS) systems or manual record-keeping. COGS includes the direct costs associated with producing the cups, such as paper, ink, and labor. Inventory levels should be monitored to prevent stockouts or overstocking. Regular analysis of these metrics helps identify areas for improvement in efficiency and profitability. For instance, tracking COGS allows for identifying opportunities to negotiate better prices with suppliers or streamline production processes.

Cash Flow Management and Financial Stability

Effective cash flow management is crucial for the financial stability of any business. This involves carefully monitoring cash inflows (revenue) and outflows (expenses) to ensure sufficient funds are available to meet operational needs. Strategies for managing cash flow include developing a realistic budget, collecting payments promptly from customers, negotiating favorable payment terms with suppliers, and securing lines of credit or other forms of financing as needed. Maintaining adequate cash reserves is vital to handle unexpected expenses or periods of low sales. A detailed cash flow projection, similar to the profit and loss projection, is crucial to anticipate potential shortfalls and plan accordingly. For example, seasonal fluctuations in demand might require borrowing to cover expenses during slower periods.

Profit Management and Investment for Long-Term Growth, How to start a paper cup business

Once the business achieves profitability, a plan for managing and investing profits is essential for long-term growth. This plan should consider reinvesting a portion of profits back into the business to expand production capacity, improve technology, or enhance marketing efforts. Another portion might be allocated to debt reduction, while a smaller part could be reserved for dividends or owner withdrawals. The specific allocation depends on the business’s financial goals and risk tolerance. For example, reinvesting profits in new equipment could significantly increase production efficiency and reduce unit costs, leading to higher profits in the future. Alternatively, investing in marketing campaigns could expand the customer base and drive sales growth.