How much does it cost to start a hat business? That’s the burning question for aspiring milliners, and the answer, as you’ll soon discover, isn’t a simple number. It depends heavily on your scale of operations, from a small home-based venture to a larger-scale production. We’ll break down the crucial costs involved, from initial investments in materials and equipment to ongoing expenses like marketing and legal fees, offering a comprehensive guide to help you budget effectively and launch your hat-making enterprise successfully.

This guide will delve into the specifics of each cost category, providing realistic examples and strategies for minimizing expenses without sacrificing quality or your brand’s vision. We’ll examine different production methods, marketing approaches, and sales channels to help you create a financial plan tailored to your hat business goals. Get ready to unravel the financial intricacies of starting your own hat business.

Startup Costs: How Much Does It Cost To Start A Hat Business

Launching a hat business requires careful consideration of initial investment. Understanding the various costs involved is crucial for creating a realistic budget and ensuring a successful launch. This section breaks down the key expenses you’ll encounter, offering a framework for planning your financial resources.

Initial Investment Breakdown

Starting a hat business necessitates investment in materials, equipment, and software. The following table provides a sample breakdown of these costs. Note that these figures are estimates and can vary significantly depending on the scale of your operation, the quality of materials chosen, and your location.

| Item | Quantity | Unit Cost | Total Cost |

|---|---|---|---|

| Fabric (various types) | 10 yards | $10/yard | $100 |

| Thread (various colors) | 5 spools | $5/spool | $25 |

| Embellishments (buttons, ribbons, etc.) | Assorted | $50 | $50 |

| Sewing Machine (industrial or high-quality home machine) | 1 | $300 – $1000 | $300 – $1000 |

| Hat Blocks (various sizes) | 5 | $20/block | $100 |

| Measuring Tools (tape measure, ruler) | 1 set | $20 | $20 |

| Design Software (Adobe Illustrator, etc. or free alternatives) | 1 license/subscription | $0 – $60/month | $0 – $720/year |

| Inventory Management Software (Spreadsheet or dedicated software) | 1 license/subscription | $0 – $50/month | $0 – $600/year |

| Website and E-commerce Platform (Shopify, Wix, etc.) | 1 | $0 – $300/month | $0 – $3600/year |

| Marketing and Advertising (initial campaign) | 1 | $500 – $2000 | $500 – $2000 |

Material Sourcing: Wholesale vs. Retail

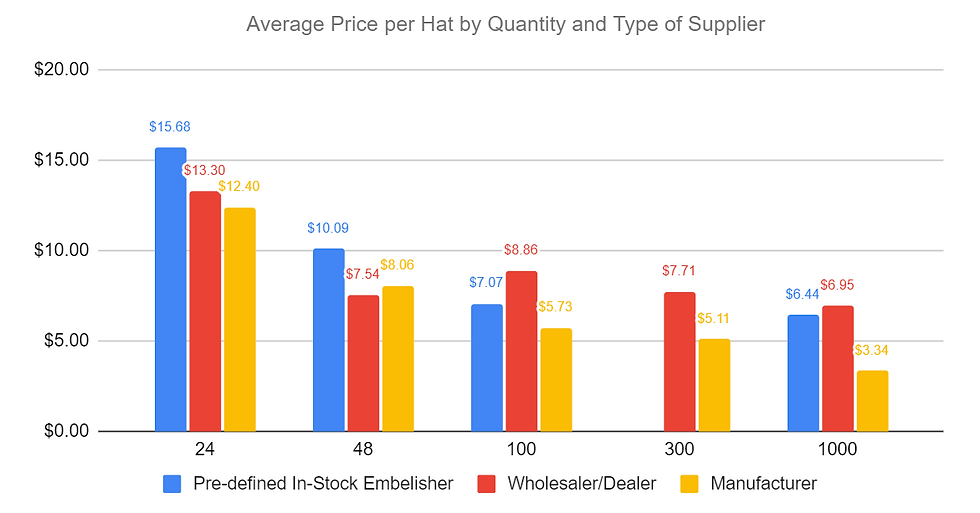

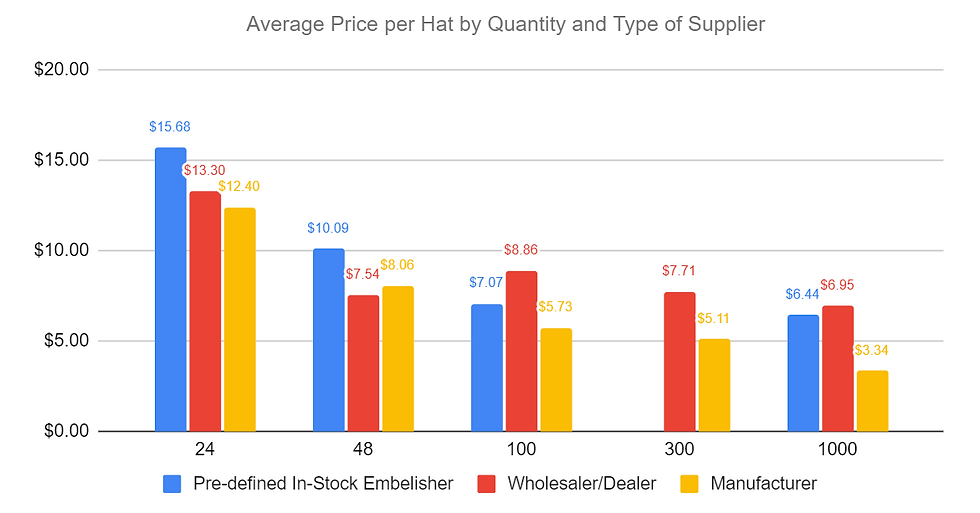

Sourcing materials efficiently is critical for profitability. Wholesale purchasing generally offers significant cost savings compared to retail. Wholesale suppliers provide larger quantities of materials at discounted prices. However, wholesale purchases require larger upfront investments and careful inventory management to avoid excess stock. Retail purchases are more convenient for smaller orders but result in higher per-unit costs. The optimal approach depends on your production volume and budget. For example, a small startup might begin with retail purchases for initial samples and gradually transition to wholesale as demand increases. A larger operation could benefit from negotiating directly with fabric mills for even greater savings.

Sample Budget for Starting a Hat Business, How much does it cost to start a hat business

The initial investment required to start a hat business varies widely. The following provides three sample budget scenarios representing low, medium, and high initial investment levels. These are estimates and can be adjusted based on specific needs and choices.

Low Investment Budget (approx. $1000 – $2000): This budget focuses on utilizing affordable materials, secondhand equipment (perhaps a used sewing machine), and free or low-cost software. Marketing efforts would be primarily organic, leveraging social media and word-of-mouth. Production volume would be limited.

Medium Investment Budget (approx. $5000 – $10,000): This budget allows for higher-quality materials, a new mid-range sewing machine, and potentially some paid advertising. A basic e-commerce website would be established. Production volume would be moderate.

High Investment Budget (approx. $15,000 – $30,000 or more): This budget supports investment in high-quality materials, professional-grade equipment (including multiple sewing machines), advanced design software, a robust e-commerce platform, and a comprehensive marketing campaign. This allows for high-volume production and significant marketing reach.

Production Costs

Understanding per-unit production costs is crucial for pricing your hats competitively and ensuring profitability. This involves a detailed breakdown of all expenses incurred in creating a single hat, from raw materials to labor and overhead. Accurate cost analysis allows for informed business decisions regarding pricing, production scale, and potential profit margins.

The cost of producing a single hat varies significantly depending on several factors, including the materials used, the complexity of the design, the production method (handmade versus mass-produced), and the location of production. Let’s examine the key cost components.

Per-Unit Cost Breakdown

To accurately calculate your per-unit cost, consider these key expense categories. These costs should be meticulously tracked to ensure accurate financial reporting and effective pricing strategies.

- Materials: This includes the cost of fabric (cotton, wool, linen, etc.), thread, interfacing, embellishments (buttons, patches, embroidery), labels, and any other materials needed for construction. The cost of these materials can fluctuate based on market prices and the quality chosen. For example, high-quality organic cotton will be more expensive than standard cotton.

- Labor: This represents the direct cost of the time and effort involved in producing the hat. For handmade hats, this is the hourly wage of the craftsperson. For mass-produced hats, it includes the cost of machine operation and worker wages. Consider factoring in any additional labor costs such as quality control checks.

- Overhead: This encompasses indirect costs associated with production, such as rent for your workshop (if applicable), utilities, equipment maintenance, packaging materials, and shipping supplies. These costs are often allocated based on the number of units produced, influencing the per-unit overhead cost.

Handmade vs. Mass-Produced Hats

The production method significantly impacts per-unit costs. Handmade hats generally command higher prices due to the higher labor costs and unique craftsmanship involved. Mass-produced hats, on the other hand, benefit from economies of scale, reducing per-unit costs, but may sacrifice some degree of individual attention to detail.

For instance, a handmade beanie using high-quality wool and intricate stitching might cost $20-$30 in materials and labor, while a mass-produced beanie made from less expensive acrylic yarn and manufactured in large quantities could cost $5-$10 per unit. The difference reflects the distinct production processes and the value associated with each approach.

Minimizing Production Costs

Strategies for reducing production costs without sacrificing quality are crucial for maintaining profitability. A balanced approach ensures that cost-cutting measures don’t negatively impact the product’s appeal and market value.

- Source Materials Efficiently: Negotiate bulk discounts with suppliers, explore alternative, cost-effective materials without compromising quality, and consider ethical and sustainable sourcing to appeal to environmentally conscious consumers.

- Optimize Production Processes: Streamline your production workflow to minimize wasted materials and time. Invest in efficient equipment if appropriate for your scale of production. Consider techniques like pattern optimization to reduce fabric waste.

- Outsource Strategically: Outsourcing certain aspects of production, such as manufacturing or embroidery, to specialized businesses can sometimes reduce costs if it’s more efficient than doing it in-house.

- Monitor and Control Overhead: Regularly review your overhead expenses and identify areas for potential cost savings, such as negotiating better rates for utilities or finding more affordable workspace.

Marketing and Sales Expenses

Launching a successful hat business requires a strategic approach to marketing and sales, balancing cost-effectiveness with reach. Ignoring this crucial aspect can severely limit your potential for growth, regardless of the quality of your products. Effective marketing isn’t just about spending money; it’s about smart spending that yields tangible results.

Cost-Effective Marketing Strategies

Several cost-effective marketing strategies can significantly boost your hat business’s visibility. These methods leverage readily available tools and platforms to maximize your marketing budget’s impact.

- Social Media Marketing: Platforms like Instagram and Pinterest are visually driven, making them ideal for showcasing hats. High-quality product photography and engaging content, including behind-the-scenes glimpses and customer testimonials, can build brand loyalty and drive sales. Utilizing relevant hashtags and running targeted ad campaigns (even with a small budget) can expand your reach significantly. Consider collaborating with micro-influencers in the fashion or lifestyle niche for authentic product endorsements.

- Online Advertising: While paid advertising can seem expensive, platforms like Google Ads and Facebook Ads offer targeted advertising options. You can set a daily or monthly budget and focus on specific demographics and interests, ensuring your ads reach the most relevant potential customers. A/B testing different ad creatives and targeting options is crucial to optimizing your return on investment.

- Local Events: Participating in local craft fairs, farmers’ markets, and community events provides direct interaction with potential customers. This allows for immediate feedback, brand building through personal connection, and the opportunity to showcase your hats in person. The cost associated with event participation is often lower than online advertising, offering a valuable return on investment through direct sales and brand exposure.

Sample Marketing Budget

A sample marketing budget for a new hat business might look like this, assuming a total marketing budget of $1,000 for the first three months:

| Marketing Channel | Monthly Budget | Total (3 Months) |

|---|---|---|

| Social Media Marketing (organic content & paid ads) | $200 | $600 |

| Local Events (2-3 events) | $100 | $300 |

| Online Advertising (Google Ads/Facebook Ads) | $100 | $300 |

| Contingency | $0 | $100 |

| Total | $400 | $1300 |

This budget prioritizes organic social media marketing and allocates funds to paid advertising and local events. The contingency budget accounts for unexpected expenses. This allocation can be adjusted based on the specific needs and goals of the business. For instance, a business targeting a younger demographic might allocate more to social media advertising.

Comparison of Sales Channels

Choosing the right sales channels is critical for maximizing revenue and minimizing costs. Each channel offers different advantages and disadvantages.

| Sales Channel | Costs | Effectiveness |

|---|---|---|

| Etsy | Listing fees, transaction fees (typically around 6.5% + payment processing fees) | High potential reach through Etsy’s established marketplace, relatively low startup costs. Effectiveness depends on optimization, product photography, and customer service. |

| Shopify | Monthly subscription fees, transaction fees (depending on payment gateway), website design and development costs. | High control over branding and customer experience, potential for higher profit margins (no marketplace fees). Requires more investment in website development and marketing. |

| Craft Fairs | Booth fees, travel expenses, materials for display. | Direct customer interaction, potential for immediate sales. Effectiveness depends on event selection, booth presentation, and customer engagement. |

Choosing the right sales channels depends on your budget, target market, and long-term goals. A multi-channel approach, combining online and offline sales, often yields the best results.

Legal and Business Expenses

Launching a hat business involves more than just sourcing materials and designing stylish headwear. Navigating the legal landscape is crucial for long-term success, ensuring compliance and protecting your investment. This section details the essential licenses, permits, and insurance needed, along with the associated costs.

Legal and business expenses can vary significantly depending on your business structure, location, and the scale of your operations. Understanding these costs upfront is vital for accurate budgeting and financial planning. Failure to comply with relevant regulations can lead to hefty fines and legal repercussions, potentially jeopardizing your entire venture.

Business Registration and Name

Registering your business name is the foundational step in establishing your legal entity. This involves choosing a name that’s both memorable and available, then formally registering it with the relevant authorities. The cost varies depending on your location and the type of registration (sole proprietorship, LLC, etc.). For example, registering an LLC in Delaware might cost around $500, including filing fees and legal assistance, while registering a sole proprietorship might only involve a small fee for a business license in your city. Securing a federal trademark for your brand name adds another layer of protection and can cost several hundred to thousands of dollars, depending on the complexity of the application process. This expense is an investment in brand protection and should be considered carefully.

Licenses and Permits

The specific licenses and permits required for a hat business vary considerably depending on your location (local, state, and federal levels). At the local level, you might need a general business license or permit from your city or county. State-level requirements often include sales tax permits and potentially licenses related to manufacturing or wholesale operations if applicable. At the federal level, you might need an Employer Identification Number (EIN) if you plan to hire employees or operate as a corporation or partnership. The costs associated with these licenses and permits range from a few dozen dollars for a simple business license to several hundred dollars for more complex permits, depending on your location and business structure. For instance, a seller’s permit in California involves an application fee and ongoing reporting obligations.

Business Insurance

Protecting your business from unforeseen circumstances is paramount. General liability insurance is essential, covering potential claims related to property damage or bodily injury caused by your business operations. Product liability insurance protects against claims related to defects in your hats. Depending on your business model and risk profile, you may also need workers’ compensation insurance if you hire employees, professional liability insurance (if offering design services), or commercial auto insurance if you use vehicles for business purposes. The annual premiums for these insurance policies can range from several hundred to thousands of dollars, depending on your coverage level, location, and the nature of your business. For example, a small hat business might pay around $500 annually for general liability insurance, while a larger operation with employees might pay significantly more.

Ongoing Legal Compliance Costs

Maintaining legal compliance is an ongoing expense. This includes staying updated on changes in regulations, filing annual reports, and ensuring your business practices align with all relevant laws. This can involve fees for legal consultations, accounting services for tax compliance, and software subscriptions for managing regulatory requirements. The exact costs will vary depending on your business size and complexity, but budgeting for ongoing legal and compliance expenses is crucial for long-term sustainability. For example, regular legal consultations might cost several hundred dollars annually, while specialized software for tax compliance can cost several hundred dollars per year.

Website and E-commerce Costs

Establishing a strong online presence is crucial for any hat business aiming for success. A well-designed website serves as your virtual storefront, showcasing your products, building brand identity, and driving sales. The costs associated with creating and maintaining this online presence can vary significantly depending on your chosen platform and level of customization.

Website development involves several key cost components. These initial investments lay the foundation for your online sales and marketing efforts. Ongoing maintenance and potential upgrades should also be factored into your long-term budget.

Domain Registration and Hosting

Securing a domain name, your website’s address (e.g., www.yourhatcompany.com), typically costs between $10 and $15 per year. This fee covers the registration and renewal of your chosen domain. Web hosting, which involves renting server space to store your website’s files and make it accessible online, ranges from $5 to $50 per month, depending on the hosting provider and the level of service required. Factors influencing hosting costs include storage space, bandwidth (the amount of data transferred), and the level of technical support provided. For a small hat business, a shared hosting plan might suffice initially, but as your website traffic grows, you might need to upgrade to a more robust solution.

Website Design and Development

The cost of website design and development can vary dramatically. A basic, template-based website can be created for a few hundred dollars using website builders like Wix or Squarespace. However, a custom-designed website, offering greater flexibility and branding control, can cost anywhere from $1,000 to $10,000 or more, depending on the complexity and features required. This cost includes the design of the website’s layout, user interface, and functionality, as well as the development of any custom features. Consider the need for mobile responsiveness, ensuring your site functions seamlessly on all devices.

E-commerce Platform Comparison

Choosing the right e-commerce platform is a critical decision. Three popular options are Shopify, Etsy, and Wix. Shopify offers a comprehensive, scalable platform with a wide range of features, but it comes with a monthly subscription fee (ranging from $29 to $299 depending on the plan) and transaction fees. Etsy, primarily geared towards handcrafted and vintage items, charges listing fees and transaction fees, but offers a built-in marketplace with a large customer base. Wix offers a user-friendly platform with e-commerce capabilities, with pricing ranging from free (with limitations) to premium plans. The best platform for your hat business will depend on your budget, technical skills, and business goals. For example, a smaller business might start with Etsy to leverage its existing marketplace, while a larger business might opt for Shopify for its scalability and features.

Compelling Product Descriptions and High-Quality Images

High-quality product images and detailed descriptions are crucial for online sales. Professional product photography, potentially outsourced, can cost anywhere from $50 to $200 per image. Compelling product descriptions should highlight key features, benefits, and materials, appealing to the customer’s emotions and needs. For example:

- Classic Baseball Cap: A timeless design, this durable 100% cotton baseball cap features a structured crown, reinforced stitching, and an adjustable strap for a perfect fit. Available in navy, black, and grey. Imagine yourself strolling along the beach or cheering on your favorite team in this comfortable and stylish cap.

- Wide-Brimmed Sun Hat: Protect yourself from the sun in style with this elegant wide-brimmed sun hat. Crafted from lightweight, breathable straw, this hat offers UPF 50+ sun protection and a comfortable fit for all-day wear. The stylish design complements any summer outfit. Picture yourself enjoying a leisurely afternoon picnic, shielded from the harsh sun.

- Woolen Beanie: Stay warm and cozy this winter with our luxuriously soft woolen beanie. Made from 100% merino wool, this beanie is incredibly soft against the skin and provides excellent insulation. The classic ribbed design adds a touch of sophistication, making it the perfect accessory for everyday wear. Visualize yourself snuggled up by the fireplace, enjoying the warmth and comfort of this stylish beanie.

Remember, high-quality images showcasing your hats from multiple angles, on different models, and in various settings are essential for capturing customer attention and driving sales.

Packaging and Shipping Costs

Order fulfillment, encompassing packaging and shipping, represents a significant yet often underestimated cost component in launching a hat business. Efficient management of these expenses is crucial for maintaining profitability and ensuring customer satisfaction. Careful consideration of packaging materials, shipping carriers, and handling procedures can significantly impact your bottom line.

Packaging Material Costs

Choosing the right packaging materials directly affects both your costs and your brand image. The selection should balance protection of your hats during transit with cost-effectiveness and sustainability. Overly expensive or extravagant packaging may be unnecessary, while insufficient protection leads to damaged goods and dissatisfied customers.

| Packaging Material | Cost per Unit | Quantity Needed (Estimate) | Total Estimated Cost |

|---|---|---|---|

| Cardboard Boxes (various sizes) | $0.50 – $2.00 | 1000 | $500 – $2000 |

| Tissue Paper | $0.05 – $0.15 per sheet | 2000 | $100 – $300 |

| Custom Printed Labels | $0.10 – $0.50 per label | 1000 | $100 – $500 |

| Bubble Wrap/Protective Inserts | $5 – $20 per roll | 5 | $25 – $100 |

Shipping Costs and Carrier Selection

Shipping costs vary considerably depending on the carrier (e.g., USPS, UPS, FedEx), the shipping method (e.g., ground, express), the package weight and dimensions, and the destination. Negotiating rates with carriers, particularly for high-volume shipments, can significantly reduce these expenses. Utilizing online shipping calculators provided by carriers helps in estimating costs before purchase.

| Shipping Carrier | Shipping Method | Estimated Cost per Package (Example: 1 lb package to a US address) | Considerations |

|---|---|---|---|

| USPS | First-Class Package | $4 – $8 | Best for lightweight, smaller packages. |

| USPS | Priority Mail | $8 – $15 | Faster delivery than First-Class. |

| UPS | Ground | $8 – $18 | Cost-effective for heavier packages. |

| FedEx | Ground | $8 – $18 | Comparable to UPS Ground. |

Minimizing Shipping Costs

Several strategies can help minimize shipping costs without compromising delivery reliability. Optimizing package size to minimize wasted space, negotiating bulk shipping rates with carriers, and offering free shipping above a certain order value (absorbing some shipping costs) are effective methods. Utilizing lighter packaging materials also contributes to cost reduction. Offering customers choices in shipping speed, with varying price points, allows them to select the option that best suits their needs and budget.

Impact of Packaging on Brand Perception

Packaging is a critical component of brand building and customer experience. High-quality, aesthetically pleasing packaging enhances brand perception, conveys professionalism, and creates a positive first impression. Sustainable packaging options, such as recycled materials or biodegradable alternatives, can resonate with environmentally conscious consumers, boosting brand image. Conversely, poorly designed or damaged packaging can negatively impact customer perception and lead to negative reviews. The inclusion of branded elements, such as custom-printed labels or inserts with a thank you note, further strengthens brand identity and enhances the overall unboxing experience.