How to start an epoxy flooring business? This isn’t just about pouring resin; it’s about building a profitable enterprise. From understanding the competitive landscape and crafting a solid business plan to mastering the installation process and securing clients, this guide navigates you through every crucial step. We’ll delve into the legal requirements, essential equipment, effective marketing strategies, and pricing models, equipping you with the knowledge to launch a thriving epoxy flooring business.

This comprehensive guide breaks down the process into manageable stages, offering practical advice and actionable strategies. Whether you’re a seasoned contractor looking to diversify or a budding entrepreneur with a passion for aesthetics and functionality, this roadmap provides the foundation for success. We’ll cover everything from market analysis and financial projections to safe handling of materials and effective customer acquisition, ensuring you’re well-prepared for the challenges and rewards of this exciting industry.

Market Research and Business Planning

Launching a successful epoxy flooring business requires meticulous planning and a thorough understanding of the market. This involves analyzing your competition, identifying your ideal customer, and developing a robust business strategy that accounts for both startup and ongoing costs. A well-defined plan is crucial for securing funding, managing resources, and achieving sustainable growth.

Effective market research and business planning are intertwined. Your market analysis directly informs your business plan, shaping your target market, marketing strategies, and financial projections. Ignoring this crucial step can lead to wasted resources and ultimately, business failure. This section will detail the necessary steps to conduct thorough market research and create a comprehensive business plan for your epoxy flooring venture.

Competitive Landscape Analysis

A comprehensive competitive analysis involves identifying all existing epoxy flooring businesses within your target geographic area. This includes both direct competitors (offering similar services) and indirect competitors (offering alternative flooring solutions). For each competitor, gather information on their pricing (per square foot, project-based pricing, etc.), service offerings (residential, commercial, industrial), marketing strategies (online presence, local advertising), and customer reviews (through online platforms like Yelp or Google My Business). This data will help you determine your competitive advantage and inform your pricing and marketing strategies. For example, if you notice a gap in the market for eco-friendly epoxy flooring, you could position your business to fill that niche. Analyzing competitor websites and social media profiles will also provide valuable insights into their marketing approaches.

Business Plan Development

A detailed business plan is your roadmap to success. It should include a clear definition of your target market (e.g., homeowners, commercial property managers, industrial facilities), your unique selling proposition (USP), your marketing strategy, and your financial projections. The following table Artikels key elements and associated costs and timelines:

| Item | Description | Cost | Timeline |

|---|---|---|---|

| Business Registration & Licenses | Securing necessary permits and licenses to operate legally. | $500 – $2000 (varies by location) | 1-3 months |

| Insurance | General liability and workers’ compensation insurance. | $1000 – $3000 per year | 1 month |

| Equipment Purchase | Mixers, spreaders, polishers, safety equipment. | $5000 – $20000 | 2-4 weeks |

| Marketing & Advertising | Website development, online advertising, local marketing materials. | $2000 – $5000 per year | Ongoing |

| Operating Expenses (Rent, Utilities, Transportation) | Monthly costs associated with running the business. | $1000 – $5000 per month | Ongoing |

| Initial Marketing Campaign | Targeted advertising to reach your ideal customer. | $1000 – $3000 | 1-3 months |

| Contingency Fund | Buffer for unexpected expenses. | $2000 – $5000 | Immediately |

These figures are estimates and will vary significantly depending on your location, scale of operations, and chosen equipment. It’s crucial to conduct thorough research to obtain accurate cost estimates for your specific circumstances.

Marketing Plan

Your marketing plan should detail how you will reach potential clients. Effective strategies include:

A multi-faceted approach is recommended. Consider allocating a budget across several channels to maximize reach and impact. Consistent brand messaging and high-quality visuals are key to establishing credibility and trust.

| Strategy | Description | Estimated Cost |

|---|---|---|

| Website Development | Professional website showcasing services, portfolio, and contact information. | $1000 – $5000 |

| Search Engine Optimization () | Improving website ranking in search engine results. | $500 – $2000 per month |

| Social Media Marketing (Facebook, Instagram) | Creating engaging content and running targeted ads. | $500 – $1500 per month |

| Local Partnerships | Collaborating with contractors, builders, and real estate agents. | Variable, potentially free through networking |

| Online Advertising (Google Ads, etc.) | Targeted advertising campaigns to reach specific demographics. | $500 – $2000 per month |

| Local Networking Events | Attending industry events and building relationships. | Variable, depending on event costs |

Legal and Regulatory Requirements

Launching an epoxy flooring business necessitates navigating a complex web of legal and regulatory requirements. Failure to comply can result in significant fines, legal action, and reputational damage. Understanding and adhering to these regulations is crucial for the long-term success and sustainability of your enterprise. This section Artikels the key legal and regulatory aspects you need to address.

Business Registration and Licensing

Registering your business and obtaining the necessary licenses are fundamental first steps. The specific requirements vary significantly by location (city, county, state, and country). Generally, you’ll need to choose a business structure (sole proprietorship, LLC, partnership, etc.), register your business name, and obtain any required local, state, and federal licenses and permits. This may include general business licenses, contractor’s licenses (potentially specialized for flooring), and potentially permits for handling hazardous materials like epoxy resins. Thorough research into your specific jurisdiction’s requirements through your local government websites or contacting business licensing departments is essential. For example, in many US states, a contractor’s license might necessitate passing a trade exam and providing proof of insurance. In other countries, similar professional registration schemes exist.

Insurance Requirements

Adequate insurance coverage is paramount to protect your business from potential liabilities. This typically includes general liability insurance, which covers bodily injury or property damage caused during your operations. Workers’ compensation insurance is crucial if you employ others, protecting them against workplace injuries. Commercial auto insurance is necessary if you use vehicles for business purposes. Depending on the nature of your work and the materials you handle, you may also need additional coverage, such as pollution liability insurance to address potential environmental hazards associated with epoxy resin spills or disposal. The specific types and amounts of insurance you need will depend on your location, the size of your business, and the nature of your operations; consulting with an insurance broker specializing in contractor insurance is highly recommended.

Safety Plan and Personal Protective Equipment (PPE)

Epoxy resins and hardeners are hazardous materials requiring stringent safety protocols. A comprehensive safety plan is crucial for the health and well-being of your employees and clients.

The following is a crucial aspect of your safety plan and should be meticulously followed:

- Hazard Identification and Risk Assessment: Identify all potential hazards associated with epoxy flooring installation, including chemical exposure, fire hazards, and physical hazards like slips, trips, and falls.

- Personal Protective Equipment (PPE): Mandate the use of appropriate PPE, including respirators (specifically designed for epoxy fumes), safety glasses, gloves (chemical-resistant), protective clothing (coveralls), and safety footwear.

- Emergency Procedures: Develop clear emergency procedures for chemical spills, fires, and medical emergencies, including contact information for emergency services and designated emergency response personnel.

- Material Safety Data Sheets (MSDS): Obtain and review MSDS for all epoxy products used. These sheets provide crucial information on handling, storage, and emergency response procedures.

- Ventilation and Workspace: Ensure adequate ventilation in work areas to minimize exposure to epoxy fumes. Properly dispose of waste materials according to local regulations.

- Training and Education: Provide comprehensive safety training to all employees, covering hazard identification, PPE usage, emergency procedures, and safe handling of epoxy materials.

- Regular Inspections and Maintenance: Conduct regular inspections of equipment and work areas to identify and address potential hazards promptly.

Equipment and Materials Sourcing

Starting an epoxy flooring business requires a strategic approach to acquiring the necessary equipment and materials. Careful planning in this area will directly impact your profitability and the quality of your work. Understanding the different options available for sourcing, along with the properties of various epoxy materials, is crucial for success. This section details the equipment needed, compares different epoxy types, and Artikels proper storage and handling procedures.

Epoxy Flooring Equipment List

The following table Artikels the essential equipment and tools for epoxy flooring installation. Prices are estimates and can vary depending on brand, quality, and supplier. Consider leasing certain high-cost items, especially when starting, to minimize upfront investment.

| Item | Quantity | Source | Cost (USD Estimate) |

|---|---|---|---|

| Mixing Buckets (5-gallon) | 3 | Home improvement stores (e.g., Home Depot, Lowe’s), online retailers (e.g., Amazon) | $20 – $30 per bucket |

| Mixing Sticks/Paddles | 5 | Home improvement stores, online retailers | $5 – $10 per paddle |

| Floor Grinder/Sander | 1 | Equipment rental companies, online retailers (for purchase) | $100 – $200 per day rental, $1000 – $3000 for purchase |

| Vacuum Cleaner (industrial strength) | 1 | Equipment rental companies, online retailers | $50 – $100 per day rental, $500 – $1500 for purchase |

| Spiked Roller | 1 | Home improvement stores, online retailers | $50 – $100 |

| Notched Squeegee | 2 | Home improvement stores, online retailers | $20 – $40 per squeegee |

| Safety Gear (Gloves, Respirator, Eye Protection) | Multiple sets | Home improvement stores, online safety supply stores | $50 – $100 per set |

| Measuring Cups and Scales | 1 set | Home improvement stores, online retailers | $20 – $30 |

| Protective Tape and Drop Cloths | As needed | Home improvement stores, online retailers | Variable |

Epoxy Flooring Material Comparison

Several types of epoxy flooring materials are available, each with unique properties. The choice depends on the project’s specific requirements, budget, and desired aesthetic.

| Epoxy Type | Properties | Advantages | Disadvantages |

|---|---|---|---|

| 100% Solids Epoxy | High chemical resistance, excellent durability, thick film build | Superior chemical and abrasion resistance, long lifespan | Higher cost, longer curing time |

| Water-Based Epoxy | Lower VOCs, easier cleanup | Environmentally friendly, less odor | Lower chemical resistance, less durable than 100% solids |

| Solvent-Based Epoxy | Fast curing, good flow and leveling | Faster installation, smooth finish | Strong odor, potential health hazards if not properly ventilated |

| Polyaspartic Polyurea | Extremely fast curing, high durability | Very fast turnaround time, high impact resistance | High cost, requires specialized equipment for application |

Epoxy Material Storage and Handling

Proper storage and handling of epoxy materials are critical for safety and product quality. Epoxy resins and hardeners are sensitive to temperature and humidity, and improper handling can lead to premature curing, reduced performance, or health hazards.

Following these guidelines is crucial:

- Store epoxy components in a cool, dry place, away from direct sunlight and heat sources. Ideal temperature ranges are typically specified by the manufacturer on the product label.

- Keep epoxy containers tightly sealed to prevent moisture absorption and premature curing. Always follow the manufacturer’s recommended storage conditions.

- Use appropriate personal protective equipment (PPE) at all times, including gloves, respirators, and eye protection. Refer to the Safety Data Sheet (SDS) for specific safety precautions.

- Never mix more epoxy than can be used within the manufacturer’s recommended pot life. Pot life is the time the mixed epoxy remains usable before it begins to cure.

- Dispose of unused epoxy and cleaning materials according to local regulations. Never pour epoxy down the drain.

Installation Process and Techniques

Successful epoxy flooring installation requires meticulous attention to detail at each stage, from surface preparation to final curing. A well-executed installation ensures a durable, aesthetically pleasing, and long-lasting floor. Ignoring any step can lead to significant problems, impacting both the visual appeal and the structural integrity of the finished product.

Surface Preparation

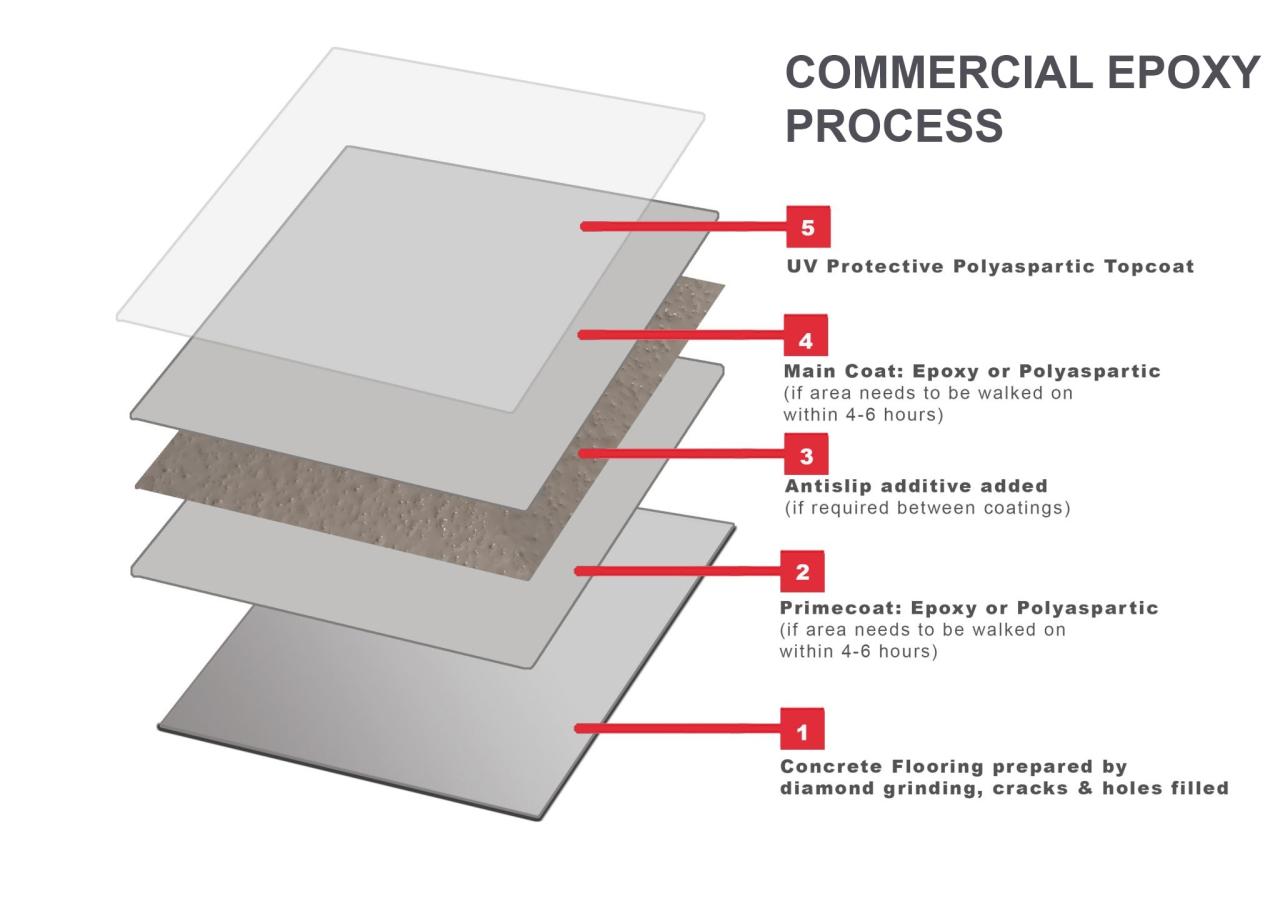

Thorough surface preparation is paramount for optimal epoxy adhesion and a flawless finish. This involves several critical steps. First, the existing floor must be completely cleaned, removing all dirt, debris, grease, and any loose or flaking materials. This often involves sweeping, vacuuming, and potentially pressure washing. Next, any cracks or imperfections in the substrate must be repaired using appropriate patching compounds, ensuring a smooth, level surface. After repairs, the surface needs to be ground using a diamond grinder to create a profile for improved epoxy bonding. Finally, a thorough cleaning is performed again to remove all dust and grinding residue. This creates a clean, receptive surface for the epoxy.

Mixing Epoxy Components

Mixing the epoxy components accurately is crucial for achieving the desired properties of the final product. The manufacturer’s instructions must be followed precisely. Typically, this involves measuring the resin and hardener components using calibrated measuring containers. These are then thoroughly mixed using a low-speed mixer for a specified amount of time to ensure complete homogenization and avoid air bubbles. Improper mixing can result in weak spots, uneven curing, and discoloration. The mixed epoxy should be a uniform color and consistency before application.

Application Techniques

Epoxy is typically applied in multiple coats, with each coat requiring careful attention to ensure even distribution and prevent air bubbles. The first coat is often a thin layer, acting as a primer, enhancing adhesion. Subsequent coats build up the desired thickness and provide the final aesthetic finish. Application techniques vary depending on the type of epoxy and the desired effect. Rollers, squeegees, and notched trowels are commonly used to achieve a smooth, even surface. The application process requires steady, controlled movements to avoid leaving streaks or air pockets. For larger areas, working in sections and ensuring wet-edge application is important to avoid lap marks.

Curing Time

The curing time for epoxy flooring depends on several factors, including the specific epoxy formulation, temperature, and humidity. Manufacturers provide recommended curing times, which should be strictly adhered to. During the curing process, it is crucial to protect the epoxy floor from foot traffic, debris, and exposure to moisture. Premature exposure to traffic or moisture can compromise the durability and appearance of the finished floor. Adequate ventilation during curing is also recommended to facilitate the chemical reaction and reduce the potential for odor buildup.

Epoxy Flooring Designs and Finishes

Different epoxy flooring designs and finishes cater to a wide range of aesthetic preferences and functional requirements.

| Design | Description |

|---|---|

| Solid Color | A single, uniform color applied throughout the floor, offering a clean, modern look. Often used in commercial and industrial settings for its durability and ease of maintenance. |

| Metallic Epoxy | Epoxy infused with metallic pigments, creating a shimmering, reflective surface. Popular for its luxurious appearance and often used in high-end residential or commercial spaces. |

| Flake Epoxy | Epoxy mixed with decorative flakes of various colors and sizes, resulting in a textured, multi-dimensional surface. Offers a unique and visually appealing finish, often used in garages or showrooms. |

| Quartz Epoxy | Epoxy combined with quartz aggregates, creating a durable, slip-resistant surface. Commonly used in high-traffic areas requiring both aesthetics and functionality. |

Troubleshooting Common Problems

Several common issues can arise during epoxy flooring installation. Uneven surfaces can result from inadequate surface preparation or improper application. Air bubbles can be caused by insufficient mixing, rapid application, or improper tool usage. Discoloration might stem from using contaminated materials, inadequate mixing, or exposure to contaminants during curing. Preventing these problems requires meticulous attention to detail at each stage of the installation process. Addressing these issues often involves grinding, re-application, or using specialized repair products, depending on the severity and cause of the problem.

Pricing and Sales Strategies: How To Start An Epoxy Flooring Business

Developing a robust pricing and sales strategy is crucial for the success of any epoxy flooring business. This involves carefully considering all costs associated with each project, establishing competitive yet profitable pricing, and implementing effective sales techniques to acquire and retain clients. A well-defined system for managing customer interactions will also streamline operations and contribute to overall efficiency.

Pricing for epoxy flooring projects should be based on a comprehensive cost analysis. This includes the cost of materials (epoxy resin, hardeners, pigments, primers, etc.), labor costs (including wages, benefits, and potential subcontractor fees), overhead expenses (rent, utilities, insurance, marketing), and the desired profit margin. Different pricing models can be employed, such as per-square-foot pricing, project-based pricing, or value-based pricing, each with its own advantages and disadvantages. For example, per-square-foot pricing offers simplicity, while project-based pricing allows for greater flexibility in accounting for complex projects. Value-based pricing focuses on the perceived value of the service, justifying higher prices for premium finishes or specialized installations.

Pricing Structure Rationale, How to start an epoxy flooring business

A clear understanding of your cost structure is paramount. Accurate material cost estimations are vital, factoring in potential price fluctuations. Labor costs should account for the time and skill level required for each project, including preparation, application, and cleanup. Overhead costs should be allocated fairly across projects. Finally, the desired profit margin should reflect the business’s financial goals and market competitiveness. A realistic profit margin will ensure the business’s long-term viability and ability to reinvest in growth. A formula to consider might be:

Price = (Material Cost + Labor Cost + Overhead Cost) / (1 – Desired Profit Margin)

. For instance, if material costs are $500, labor costs are $1000, overhead is $200, and the desired profit margin is 20%, the price would be ($500 + $1000 + $200) / (1 – 0.2) = $1700 / 0.8 = $2125.

Effective Sales Strategies

Attracting and retaining clients requires a multi-pronged approach. Building a strong online presence through a professional website and targeted social media marketing is essential. Showcasing a portfolio of high-quality completed projects with before-and-after photos will visually demonstrate the transformative power of epoxy flooring. Collecting and prominently displaying positive customer testimonials builds trust and social proof. Offering guarantees or warranties on workmanship and materials reassures potential clients about the quality and longevity of the work. Furthermore, participating in local trade shows and networking events provides valuable opportunities to connect with potential clients and build relationships within the community.

Customer Inquiry and Payment Management System

A well-organized system for managing customer inquiries is essential for efficient operations. This could involve a dedicated email address, a contact form on the website, or a phone line. A scheduling system, such as online booking software or a shared calendar, helps manage appointments effectively. Clear communication with clients throughout the project lifecycle is crucial. Multiple payment options should be offered, including credit cards, checks, and potentially financing options, to cater to diverse client preferences. Secure payment processing systems are necessary to protect both the business and the client’s financial information. Finally, detailed invoicing and record-keeping practices are vital for accurate financial tracking and compliance.