Is laser engraving a good business? The short answer is: it depends. Success hinges on a well-defined business plan, understanding your local market, and a keen eye for both operational efficiency and effective marketing. This detailed exploration delves into the key factors determining profitability, from startup costs and competitive analysis to marketing strategies and legal compliance, offering a comprehensive guide to help you make an informed decision.

This guide covers crucial aspects, including market research to assess demand and competition, a thorough breakdown of startup costs and ongoing expenses, effective marketing strategies to attract and retain clients, and the operational procedures involved in running a successful laser engraving business. We’ll also examine the legal and regulatory considerations necessary for smooth operation and compliance.

Market Demand & Competition

The laser engraving market presents a compelling opportunity for entrepreneurs, but success hinges on understanding the existing landscape. This includes assessing market size, analyzing competitor pricing, and identifying potential growth areas within specific niches. A thorough market analysis is crucial for developing a viable business plan and achieving profitability.

Determining the precise market size for laser engraving services within a specific geographic area requires localized market research. This could involve surveying local businesses, analyzing online advertising spend by competitors, or consulting industry reports specific to your region. However, national data can offer a general indication. Reports from market research firms often provide estimates of the overall market size for personalized products, a segment that includes laser engraving. These reports usually segment the market by product type, customer demographics, and geographic location, offering a valuable starting point for more detailed local research.

Competitor Pricing Analysis

Understanding the pricing strategies of established competitors is vital for developing a competitive pricing model. Direct observation and online research can reveal pricing for common engraving items. The following table shows hypothetical pricing examples, remember to conduct your own research for accurate data in your target area.

| Item | Competitor A | Competitor B | Competitor C |

|---|---|---|---|

| Mug (11oz) | $15 | $12 | $18 |

| Pen | $8 | $7 | $10 |

| Wood Plaque (8×10 inches) | $30 | $25 | $35 |

Market Growth Potential

The laser engraving market shows potential for continued growth. Several factors contribute to this, including the rising popularity of personalized gifts, increasing demand for customized corporate merchandise, and the expansion of e-commerce platforms that facilitate the sale of engraved products. For example, the growth of online marketplaces like Etsy has provided a significant boost to small businesses offering personalized goods, including laser-engraved items. Furthermore, demographic trends, such as the increasing disposable income of millennials and Gen Z who value unique and personalized items, fuel this growth.

Beneficial Business Segments

Several business types benefit significantly from laser engraving services. Corporate clients frequently utilize laser engraving for customized gifts, promotional items, and employee awards. The ability to add a company logo or personalized message enhances the perceived value of these items. Additionally, small businesses selling personalized items, such as jewelry, home decor, or pet accessories, can leverage laser engraving to differentiate their products and add a premium touch. The craft and hobby market also represents a significant opportunity, with individuals using laser engraving to create unique items for sale or personal use. Furthermore, the educational sector, including schools and universities, may utilize laser engraving for customized trophies, awards, and educational materials.

Startup Costs & Expenses: Is Laser Engraving A Good Business

Launching a laser engraving business requires a significant upfront investment in equipment and ongoing operational costs. Understanding these expenses is crucial for creating a realistic business plan and securing necessary funding. This section details the initial capital expenditure, recurring operational expenses, and a simplified financial projection to illustrate the financial landscape of this venture.

Equipment Costs

The core of your laser engraving business is the laser engraver itself. Beyond the machine, several ancillary tools and software are essential for efficient and high-quality operation. The following table provides a cost estimate for essential equipment. Note that prices can vary significantly based on brand, specifications, and supplier. These figures represent a mid-range estimate for a viable startup.

| Item | Description | Estimated Cost (USD) | Supplier Example |

|---|---|---|---|

| Laser Engraver | CO2 laser engraver with sufficient power and work area for your intended projects. | $5,000 – $15,000 | OMTech, Glowforge, Epilog |

| Computer | High-performance computer for running engraving software and managing designs. | $1,000 – $2,000 | Dell, HP, Apple |

| Engraving Software | Software for designing and controlling the laser engraver (e.g., LightBurn, LaserGRBL). | $100 – $300 | LightBurn Software, Grbl Control |

| Air Compressor (optional) | For assisting with material removal and dust collection. | $200 – $500 | Harbor Freight, Campbell Hausfeld |

| Exhaust System (optional but recommended) | Crucial for ventilation and safety, especially with CO2 lasers. | $500 – $1,500 | Various industrial ventilation suppliers |

| Safety Equipment | Laser safety glasses, gloves, and fire extinguisher. | $200 – $500 | Amazon, Safety supply stores |

| Materials Handling Equipment | Work tables, material storage, etc. | $500 – $1,000 | Local hardware stores |

Ongoing Operational Expenses

Beyond the initial equipment investment, ongoing operational expenses are critical to consider. These recurring costs impact your profitability and need careful budgeting.

These expenses include:

- Rent: Cost of workspace, potentially including utilities. This could range from $500 to $2,000 per month depending on location and size.

- Utilities: Electricity (significant for laser operation), water, and internet. Estimate $200-$500 monthly.

- Marketing & Advertising: Online advertising, social media marketing, local business listings. Budget $100-$500 monthly.

- Supplies: Laser engraving materials (wood, acrylic, metal, etc.), cleaning supplies, and maintenance items. This is highly variable based on project volume and material choices, but expect $200-$1000 monthly.

- Insurance: Business liability and equipment insurance. Costs vary based on coverage and location.

Financial Model: First-Year Projection

This is a simplified example and actual results will vary. Assume a monthly revenue projection of $5,000 after the first three months, increasing to $7,000 by the end of the year.

Total Startup Costs (Equipment + Initial Marketing): $8,000 – $20,000 (depending on equipment choices)

Monthly Expenses (Rent + Utilities + Marketing + Supplies): $1,000 – $2,500

Annual Revenue (conservative estimate): $50,000 – $84,000

Profit (Revenue – Expenses): $26,000 – $64,000 (after the first year, assuming consistent sales growth)

Leasing vs. Purchasing Equipment

Leasing offers lower upfront costs but higher overall expenses over time. Purchasing provides ownership and potential tax benefits but requires a larger initial investment. The best option depends on your financial situation and business goals. For example, leasing might be suitable for startups with limited capital, while purchasing is preferable for businesses anticipating significant growth and long-term operation. Thorough financial analysis comparing lease payments and total ownership costs is recommended before making a decision.

Marketing & Sales Strategies

A successful laser engraving business requires a robust marketing and sales strategy to attract customers, secure repeat business, and ultimately, achieve profitability. This involves a multi-pronged approach encompassing online and offline channels, targeted messaging, and competitive pricing. The key is to clearly communicate the value proposition – personalized, high-quality, and durable products – to the right audience.

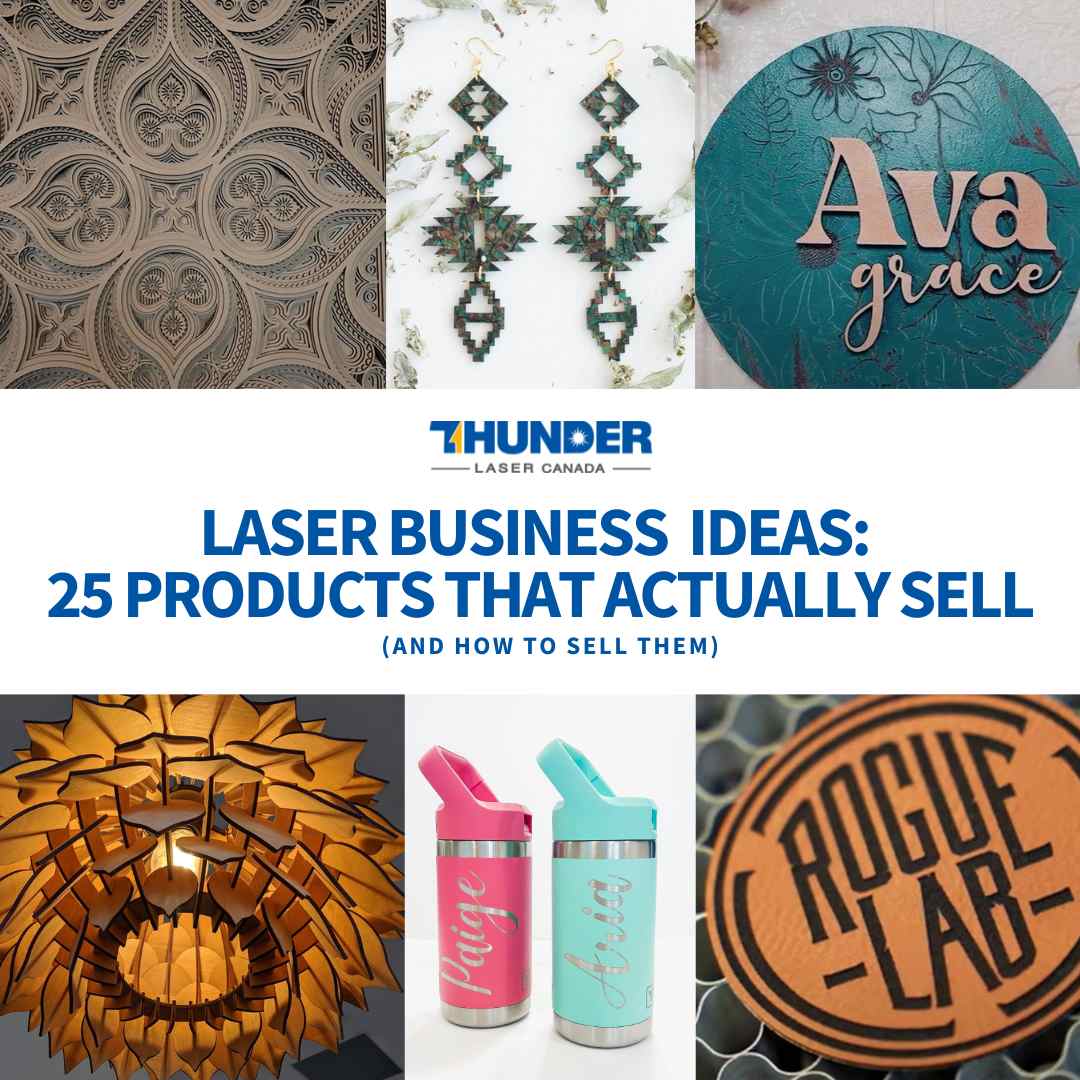

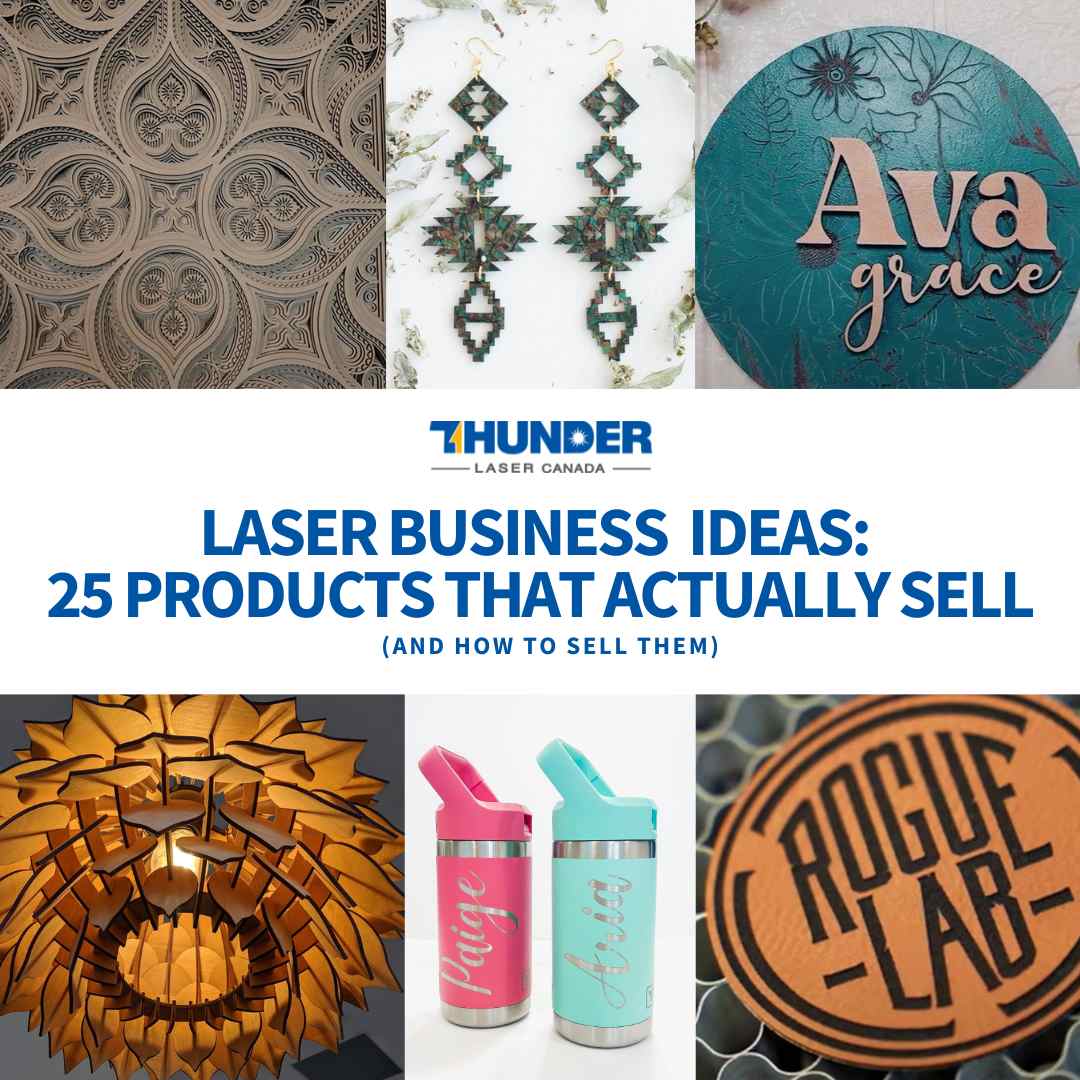

Social Media Marketing Strategies

Social media platforms offer a cost-effective way to reach a wide audience and build brand awareness. A strong visual presence is crucial for laser engraving, as the intricacy and beauty of the finished products are best showcased through high-quality images and videos. Strategies should focus on platforms like Instagram and Facebook, where visually appealing content thrives. Regular posting of customer projects, behind-the-scenes glimpses of the engraving process, and promotional offers will keep the audience engaged. Utilizing relevant hashtags will increase visibility and reach a wider audience interested in personalized gifts, custom products, or specific materials used in the engraving process. Paid advertising campaigns on these platforms can further amplify reach and target specific demographics. For example, a campaign targeting small business owners could showcase how laser engraving can enhance their branding with custom logo products.

Local Advertising and Online Marketplaces

Complementing online strategies, local advertising builds brand presence within the immediate community. This could involve flyers distributed to local businesses, advertisements in community newspapers or magazines, and participation in local craft fairs or markets. Online marketplaces such as Etsy and Shopify provide additional avenues to reach potential customers beyond a localized area. These platforms offer built-in marketing tools and a large customer base actively searching for unique and personalized items. A well-optimized online store with high-quality product photography and detailed descriptions is essential for success on these platforms. For instance, an Etsy shop showcasing personalized pet portraits engraved on wood or metal could attract a significant number of pet owners searching for unique gifts.

Marketing Materials Examples

Effective marketing materials should highlight the benefits of laser engraving: personalization, durability, and speed of production. Website copy could emphasize the ability to create unique gifts for any occasion, while social media posts could showcase the versatility of laser engraving across various materials (wood, acrylic, metal, etc.). For example, a Facebook post could feature a before-and-after image of a plain wooden box transformed into a beautifully engraved keepsake. Website copy should include clear calls to action, encouraging visitors to request a quote or browse the product catalog. Social media posts should include engaging captions that encourage interaction and sharing, such as “Tag someone who would love this personalized gift!”

Pricing Strategy, Is laser engraving a good business

A well-defined pricing strategy balances profitability with market competitiveness. This requires considering material costs, labor costs, machine operation costs, and the time invested in design and production. Analyzing competitor pricing provides valuable insights into market rates. A tiered pricing structure might be implemented, offering various packages based on the complexity and size of the project. For instance, a basic package could include a smaller engraving area and simpler designs, while a premium package could include larger engravings, intricate designs, and additional customization options. Offering discounts for bulk orders or repeat customers can further incentivize sales.

Building Client Relationships and Securing Repeat Business

Building strong client relationships is crucial for securing repeat business and generating referrals. Exceptional customer service, prompt communication, and exceeding customer expectations are key elements. Collecting customer feedback through surveys or reviews provides valuable insights into areas for improvement and helps to build trust. A loyalty program, offering discounts or exclusive offers to repeat customers, can encourage repeat business. Regular email newsletters showcasing new products, special offers, and design ideas can also help to maintain engagement and remind customers of the business’s services. For example, offering a 10% discount on a customer’s next order after their first purchase can significantly improve customer retention.

Production & Operations

Efficient production and operations are crucial for the success of any laser engraving business. This involves a streamlined workflow, from initial design to final delivery, coupled with a keen understanding of materials and inventory management. Careful planning in this area directly impacts profitability and customer satisfaction.

Laser Engraving Process: Design to Product

The laser engraving process begins with the design phase. This involves using vector-based graphic design software like Adobe Illustrator or CorelDRAW to create the artwork. Raster images can be used, but vector graphics generally produce cleaner, more precise results. The design is then prepared for the laser engraver by ensuring it’s in the correct file format (typically SVG, DXF, or AI) and optimized for the machine’s capabilities. The file is then sent to the laser engraver, where the machine uses a high-powered laser beam to precisely remove material from the surface of the chosen substrate, creating the desired engraved design. The process requires careful calibration of laser power, speed, and focal point to achieve optimal results and prevent damage to the material. Different materials require different settings to avoid burning or incomplete engraving. Post-processing might involve cleaning the engraved item or applying a protective finish, depending on the material and desired effect.

Suitable Materials for Laser Engraving

The choice of material significantly impacts the final product’s quality and cost. Different materials respond differently to laser engraving, requiring adjustments to the laser settings. Selecting the appropriate material is critical for a successful outcome.

- Wood: A popular choice offering diverse grains and colors. Laser engraving produces a clean, crisp finish. Different wood types have varying densities and burn rates, requiring adjustments to laser settings. Examples include plywood, cherry, walnut, and maple.

- Acrylic: Offers a smooth, polished surface and is available in various colors and thicknesses. Laser engraving can create clear, detailed designs. The melting properties of acrylic allow for interesting effects like color changes or internal engraving.

- Leather: A versatile material suitable for personalizing accessories. Laser engraving produces a slightly etched or darkened mark depending on the leather type and laser settings. The result is often a subtle and elegant design.

- Metal: Certain metals like stainless steel and aluminum can be engraved, though it often requires higher power and specialized settings. The process often results in a slightly darkened or etched effect rather than material removal.

- Glass: Can be engraved, but it’s more challenging due to its hardness and the risk of shattering. Often requires specialized techniques and settings.

Inventory Management for Laser Engraving

Effective inventory management is key to minimizing waste and ensuring timely order fulfillment. This involves tracking stock levels of materials, monitoring usage rates, and implementing a system for replenishing supplies. A well-organized inventory system helps avoid stockouts while preventing unnecessary accumulation of materials. Using inventory management software or spreadsheets can greatly assist in tracking and forecasting demand. Regular stocktaking and waste analysis can help identify areas for improvement in material usage and ordering practices. For example, tracking the amount of wood wasted per project allows for more accurate material purchasing in the future.

Customer Order Handling: A Step-by-Step Guide

Efficient customer order handling is essential for building a positive customer experience. A well-defined process ensures orders are processed smoothly and efficiently.

- Order Reception: Receive orders through various channels (e.g., online store, email, phone). Clearly communicate order details and estimated delivery time.

- Design Confirmation: Confirm the design with the customer, addressing any queries or revisions. Provide mock-ups if necessary.

- Production: Prepare the design file for laser engraving and execute the engraving process.

- Quality Control: Inspect the finished product for quality and accuracy, ensuring it meets the customer’s specifications.

- Packaging and Shipping: Package the product securely and ship it using a reliable shipping method. Provide tracking information to the customer.

- Post-Delivery Follow-up: Follow up with the customer to ensure satisfaction and gather feedback.

Legal & Regulatory Compliance

Operating a laser engraving business requires navigating a complex landscape of legal and regulatory requirements to ensure both your safety and the safety of your employees and the environment. Failure to comply can result in hefty fines, legal action, and reputational damage. Understanding and adhering to these regulations is crucial for long-term business success.

Required Licenses and Permits

Securing the necessary licenses and permits is a foundational step in establishing a legitimate laser engraving business. The specific requirements vary significantly depending on your location (city, county, state, and country). These may include business licenses, zoning permits (to ensure your chosen location is suitable for industrial operations), and potentially specialized permits related to the use of lasers and handling of specific materials. It’s essential to contact your local government agencies, such as the Small Business Administration (SBA) and your city or county clerk’s office, to determine the precise permits needed for your business. Failing to obtain the necessary permits before commencing operations can lead to legal repercussions and operational shutdowns. Thorough research and proactive engagement with regulatory bodies are vital.

Laser Engraving Equipment Safety Precautions

Safe operation of laser engraving equipment is paramount. Negligence in this area can result in serious injury or damage to property. A comprehensive safety program must be implemented and strictly followed.

- Eye Protection: Laser beams can cause irreversible eye damage. All personnel operating or in proximity to the laser engraver must wear appropriate laser safety eyewear rated for the specific wavelength and power output of your laser.

- Protective Clothing: Protective clothing, such as long sleeves, gloves, and closed-toe shoes, should be worn to minimize skin exposure to laser radiation and potential hazards from material handling.

- Ventilation: Adequate ventilation is crucial to remove potentially harmful fumes and dust generated during the engraving process. A well-ventilated workspace, or the use of local exhaust ventilation systems, is essential.

- Fire Safety: Laser engraving can ignite flammable materials. Keep flammable materials away from the laser engraver and have a fire extinguisher readily available. Regular inspections of electrical wiring and equipment are also crucial.

- Emergency Procedures: Establish clear emergency procedures, including what to do in case of a laser malfunction, fire, or injury. Ensure all employees are trained on these procedures.

- Regular Maintenance: Regular maintenance and inspection of the laser engraver are essential to prevent malfunctions and ensure safe operation. This includes cleaning optical components and checking for loose wires or damaged parts.

Environmental Regulations and Waste Disposal

Laser engraving generates waste materials, including dust, fumes, and potentially hazardous materials depending on the materials being engraved. Compliance with environmental regulations regarding waste disposal is mandatory. This involves proper classification, containment, and disposal of waste according to local, state, and federal regulations. Many jurisdictions have specific guidelines for the disposal of hazardous materials. Consult your local environmental protection agency (EPA) or equivalent authority for guidance on proper waste disposal procedures. Improper disposal can result in significant environmental damage and substantial fines. Consider partnering with a licensed waste disposal company experienced in handling laser engraving waste.

Business Insurance

Comprehensive insurance coverage is crucial for protecting your laser engraving business from various risks. This should include general liability insurance to cover potential injuries or property damage caused by your business operations. Product liability insurance is also recommended to protect you against claims arising from defects in your engraved products. Consider additional coverage such as equipment insurance to protect your laser engraver from damage or theft. The specific types and amounts of insurance needed will depend on the size and scope of your business and the risks involved. Consulting with an insurance professional is highly recommended to determine the appropriate coverage for your specific needs. A robust insurance policy provides financial protection and peace of mind.