Is white metal detectors still in business? Absolutely! While the market may not be as flashy as some tech sectors, the demand for reliable metal detection persists across diverse industries. From archaeology and security to mining and even hobbyist treasure hunting, these devices remain crucial tools. This exploration delves into the current state of the white metal detector industry, examining leading manufacturers, technological advancements, and the future of this enduring technology.

We’ll uncover the key players shaping the market, analyze the evolution of detector technology, and explore the various applications driving continued innovation. We’ll also address the challenges faced by manufacturers and discuss emerging trends that promise to further refine and expand the capabilities of white metal detectors in the years to come. Get ready to discover a world of hidden potential beneath the surface.

White Metal Detector Companies

The white metal detector market, while niche, comprises several key players offering diverse products and technologies. Understanding the market landscape requires examining the prominent manufacturers, their technological strengths, and their market positioning. This analysis will focus on identifying major players, comparing their offerings, and providing relevant information for those interested in the industry.

Major Players in the White Metal Detector Industry

Identifying the precise market share for each company is difficult due to the lack of publicly available, comprehensive market data specific to “white” metal detectors (as opposed to general metal detectors). However, several companies are recognized for their production and distribution of metal detectors frequently used in applications where the detection of white metals (such as aluminum, zinc, or tin) is crucial. These companies often cater to diverse industries, including security, industrial inspection, and archaeology. It’s important to note that many smaller companies and specialized manufacturers may also exist but lack the visibility of larger players.

Publicly Traded Companies Specializing in White Metal Detectors

There are no publicly traded companies solely dedicated to manufacturing white metal detectors. The technology is often integrated into broader metal detection systems offered by larger companies involved in industrial automation, security systems, or other related fields. Thus, identifying specific publicly traded companies exclusively focused on white metal detection is not feasible.

Comparison of Prominent Manufacturers

A direct comparison requires specifying what constitutes “prominent.” Many companies produce metal detectors suitable for detecting white metals, but marketing materials rarely highlight this aspect specifically. Therefore, we’ll analyze three companies known for producing high-quality metal detection equipment that are applicable to scenarios involving white metal detection. The performance and suitability of these devices will depend heavily on the specific application and the required sensitivity.

| Company Name | Location | Product Highlights | Website URL |

|---|---|---|---|

| Minelab | Australia | Known for high-sensitivity detectors used in various applications, including mineral exploration, which often involves detecting white metals alongside other materials. They offer a range of features like multi-frequency operation and advanced signal processing. | www.minelab.com |

| Garrett Metal Detectors | United States | A long-standing manufacturer with a broad product line, including detectors suitable for various applications where white metal detection might be necessary. Their focus is often on ease of use and affordability. | www.garrett.com |

| Fisher Research Labs | United States | Offers a range of metal detectors, some of which are suitable for detecting white metals depending on the specific model and its sensitivity settings. They are known for their durable and reliable designs. | www.fisherlab.com |

Technological Advancements in White Metal Detectors

The past decade has witnessed significant strides in white metal detector technology, driven primarily by advancements in microelectronics, signal processing, and software development. These improvements have resulted in detectors with enhanced sensitivity, improved discrimination capabilities, and greater depth of detection, leading to more efficient and effective treasure hunting and archaeological exploration. This enhanced performance translates directly to improved user experience and more successful finds.

The evolution of white metal detector technology is characterized by a continuous refinement of existing techniques and the integration of new technologies. This progress has not only increased the power and precision of these devices but also made them more user-friendly and accessible to a wider range of users. This section will explore these advancements in detail.

Sensitivity Improvements in White Metal Detectors

Increased sensitivity is a key advancement in modern white metal detectors. This improvement stems from the use of more powerful and efficient microprocessors and improved coil design. Modern detectors employ sophisticated algorithms to process signals more effectively, minimizing noise and maximizing the detection of weak signals from deeply buried or small metal objects. For example, the introduction of multi-frequency technology allows detectors to operate across a wider range of frequencies, enhancing their ability to detect a broader spectrum of metals and overcoming the limitations of single-frequency detectors. This results in a significantly higher probability of detecting even small, deeply buried targets that would have previously gone unnoticed.

Discrimination Advancements in White Metal Detectors

Modern white metal detectors offer significantly improved discrimination capabilities compared to their predecessors. This is achieved through advanced signal processing techniques that analyze the unique electromagnetic signatures of different metals. This allows users to filter out unwanted signals from ferrous metals (like iron), focusing only on the desired targets, such as gold, silver, or other precious metals. For instance, some advanced detectors employ sophisticated algorithms that identify the conductivity and permeability of the detected metal, providing a more accurate assessment of the target’s composition. This minimizes false positives and improves the overall efficiency of the detection process.

Depth of Detection Improvements in White Metal Detectors

Advancements in coil design, signal processing, and power management have led to a notable increase in the depth of detection achievable with modern white metal detectors. Larger, more efficient coils capture a wider range of electromagnetic signals, increasing the detector’s sensitivity to targets at greater depths. Furthermore, improvements in signal processing algorithms effectively filter out ground noise and other interference, allowing the detector to discern weaker signals originating from deeper targets. For example, some high-end detectors boast a significantly increased depth penetration compared to models from a decade ago, allowing users to locate objects buried several feet beneath the surface.

Impact of Microelectronics and Signal Processing on White Metal Detector Performance

The advancements in microelectronics and signal processing have fundamentally reshaped white metal detector performance. The use of powerful, low-power microprocessors allows for the implementation of sophisticated algorithms that significantly improve sensitivity, discrimination, and depth of detection. These microprocessors enable real-time signal analysis, allowing for immediate feedback to the user and minimizing the need for complex manual adjustments. Furthermore, advancements in digital signal processing (DSP) have allowed for the development of more robust and accurate detection systems, minimizing the impact of environmental factors such as ground mineralization and electromagnetic interference.

Timeline of Significant Milestones in White Metal Detector Technology

The following timeline highlights some key advancements in white metal detector technology over the past decade:

2014: Widespread adoption of multi-frequency technology significantly improving target identification and discrimination.

2016: Introduction of improved coil designs leading to increased sensitivity and depth of detection.

2018: Development of advanced ground balancing algorithms minimizing the effects of ground mineralization.

2020: Integration of GPS and wireless connectivity for precise location tracking and data sharing.

2022: Enhanced user interfaces and improved software features for intuitive operation and data analysis.

Applications and Uses of White Metal Detectors

White metal detectors, despite their name suggesting a narrow application, find utility across a surprisingly diverse range of industries. Their ability to detect metallic objects, regardless of their size or composition, makes them invaluable tools in scenarios requiring precise location and identification of such objects. This versatility is driven by advancements in both sensor technology and signal processing capabilities, allowing for increased sensitivity and discrimination.

White metal detectors are employed in diverse settings, each demanding specific capabilities and adaptations of the core technology. The following sections detail several key applications, highlighting the unique requirements and benefits in each industry.

Security Applications of White Metal Detectors

Security checkpoints, whether at airports, government buildings, or large-scale events, benefit significantly from white metal detectors. Handheld units are frequently used for personal screening, quickly identifying concealed weapons or other metallic contraband. Larger, walk-through metal detectors are employed for mass screening, offering a rapid and efficient method to scan large numbers of individuals. These systems are often integrated with advanced alarm systems and image processing software to pinpoint the location of detected objects and minimize false alarms. The ability to quickly and accurately identify metallic threats enhances security protocols and contributes to a safer environment.

Archaeological Applications of White Metal Detectors

Archaeologists utilize white metal detectors to uncover buried artifacts and remnants of past civilizations. The sensitivity of these detectors allows for the detection of small metallic objects, such as coins, tools, or jewelry, buried beneath the surface. The ability to pinpoint the location of these artifacts minimizes damage to the surrounding site during excavation, ensuring the preservation of historical context. Different detector settings and coil sizes are used depending on the suspected depth and size of the buried objects, maximizing the efficiency of the search and minimizing the risk of missing valuable finds. For example, a smaller, more sensitive coil might be used for detecting small artifacts in a densely populated area, while a larger coil could be more efficient in covering a wider area.

Mining Applications of White Metal Detectors

In the mining industry, white metal detectors play a crucial role in ensuring safety and optimizing resource extraction. They are used to detect metallic objects, such as lost tools or equipment, within mining shafts and tunnels. This prevents accidents caused by workers inadvertently encountering these objects. Furthermore, they can be used to detect valuable metallic ores within the earth, helping to guide excavation efforts and improve the efficiency of mining operations. Specialized, ruggedized detectors are used to withstand the harsh conditions present in mines, ensuring reliable performance even in dusty, damp, or otherwise challenging environments.

Hypothetical Scenario: White Metal Detectors in Construction

Imagine a large construction site where a significant amount of underground utility lines are present. Before excavation begins, a team uses ground-penetrating radar (GPR) to create a preliminary map of the underground infrastructure. However, GPR may not be able to accurately distinguish between different types of metallic objects. To ensure worker safety and prevent damage to the utilities, a team then employs a highly sensitive white metal detector to precisely locate the position of all buried metallic pipes and cables. This detailed mapping, provided by the white metal detector, allows for safe and efficient excavation, minimizing the risk of damage to critical infrastructure and preventing potential accidents.

Types of White Metal Detectors and Ideal Applications

Three distinct types of white metal detectors, each suited to specific applications, are:

- Handheld Metal Detectors: These are portable and lightweight, ideal for security checks, archaeological surveys, and localized searches. Their maneuverability allows for detailed scans in confined spaces.

- Walk-through Metal Detectors: Used primarily in security applications for mass screening of people, these larger units are designed for high-throughput environments and provide a rapid method for detecting concealed metallic objects.

- Ground-penetrating Metal Detectors: These specialized detectors are employed in applications requiring the detection of buried metallic objects at significant depths, such as archaeology or mining. They typically incorporate more powerful coils and advanced signal processing to overcome the attenuation of signals in the earth.

Challenges and Future Trends

The white metal detector industry, while relatively niche, faces a unique set of challenges and opportunities as technology advances and market demands evolve. Manufacturers must navigate evolving regulatory landscapes, compete with increasingly sophisticated technologies, and anticipate shifts in application areas to maintain their market position. Understanding these challenges and emerging trends is crucial for both manufacturers and end-users.

Regulatory and Safety Standards

Stringent regulations and safety standards significantly impact the design, manufacturing, and deployment of white metal detectors. For instance, detectors used in food processing facilities must adhere to strict hygiene standards, requiring materials resistant to cleaning agents and preventing the accumulation of contaminants. Similarly, detectors used in security applications may need to meet specific sensitivity requirements to detect concealed weapons or contraband, while also adhering to privacy regulations. Non-compliance can lead to hefty fines, product recalls, and reputational damage. The evolving landscape of international and regional standards requires manufacturers to invest continuously in compliance testing and adaptation. For example, the FDA in the US has specific guidelines for equipment used in food production, necessitating regular audits and certifications for manufacturers to maintain their market access.

Technological Advancements and Competition

The field of metal detection is experiencing rapid technological advancements. The integration of advanced signal processing algorithms, improved sensor technologies (such as multi-frequency sensors and pulsed induction systems), and the incorporation of artificial intelligence (AI) are significantly enhancing the sensitivity, accuracy, and speed of white metal detectors. This also leads to increased competition, particularly from manufacturers offering more feature-rich and cost-effective solutions. Companies are constantly striving to develop detectors with higher sensitivity to detect smaller or more deeply buried metal fragments, improved discrimination capabilities to reduce false positives, and more user-friendly interfaces. For instance, the development of advanced signal processing algorithms allows for the effective detection of metallic contaminants even in challenging environments with high background noise.

Emerging Technologies Impacting White Metal Detectors

Several emerging technologies hold the potential to revolutionize white metal detection. The integration of AI and machine learning could significantly enhance the ability of detectors to identify and classify different types of metals, reducing false alarms and improving overall efficiency. Furthermore, the use of advanced imaging techniques, such as X-ray technology combined with metal detection, could provide a more comprehensive analysis of the material being inspected. Miniaturization of components and the use of more energy-efficient designs are also important trends, leading to smaller, lighter, and more portable detectors suitable for diverse applications. For example, a company might develop a hand-held white metal detector with AI-powered object recognition to automatically classify the detected metal as harmless or potentially dangerous, reducing the workload on human operators.

Future Applications and Market Trends

The demand for white metal detectors is expected to grow across various sectors. The increasing emphasis on food safety and quality control will drive demand in the food processing industry. The need for enhanced security measures in public spaces and critical infrastructure will boost the adoption of white metal detectors in security and surveillance applications. Furthermore, the growing demand for precision in manufacturing industries will necessitate the use of advanced metal detection systems for quality control and defect detection. Emerging applications might include using white metal detectors in recycling processes to separate valuable metals from waste materials or in environmental monitoring to detect metal contaminants in soil or water. The development of specialized detectors for specific applications, such as those designed for detecting trace amounts of heavy metals in pharmaceutical products, is also a likely trend. For example, the rising prevalence of counterfeit pharmaceuticals could drive the adoption of highly sensitive white metal detectors to ensure the authenticity and safety of medications.

Customer Reviews and Feedback: Is White Metal Detectors Still In Business

Customer reviews offer invaluable insights into the real-world performance and user experience of white metal detectors. Analyzing this feedback allows manufacturers to identify areas for improvement and provides potential buyers with realistic expectations. A composite of several reviews, both positive and negative, reveals a nuanced picture of the current market.

The following table summarizes a selection of fictionalized customer reviews, representing a range of experiences with different white metal detector brands and models. While specific brand names are omitted for neutrality, the reviews reflect common themes found in online and user forum discussions.

Customer Review Summary

| Review Source | Rating (out of 5 stars) | Pros | Cons |

|---|---|---|---|

| Online Forum – “TreasureHunter77” | 4 | Lightweight and easy to assemble; excellent depth detection for smaller objects; intuitive controls. | Battery life could be improved; occasional false signals in highly mineralized soil. |

| Retail Website – “MetalMike” | 3 | Durable construction; good value for the price; decent sensitivity. | Pinpointing accuracy could be better; somewhat heavy for extended use. |

| Independent Blog – “DiggerDan” | 5 | Exceptional depth and discrimination; waterproof design; superior pinpointing; excellent customer support. | High price point; slightly complex interface for beginners. |

| Amazon – “BeachBumBob” | 2 | Easy to use; relatively inexpensive. | Poor sensitivity; frequent false signals on the beach; cheaply made. |

| YouTube Review – “ProspectorPete” | 4.5 | Powerful signal processing; excellent discrimination capabilities; robust construction. | Slightly bulky; learning curve for advanced features. |

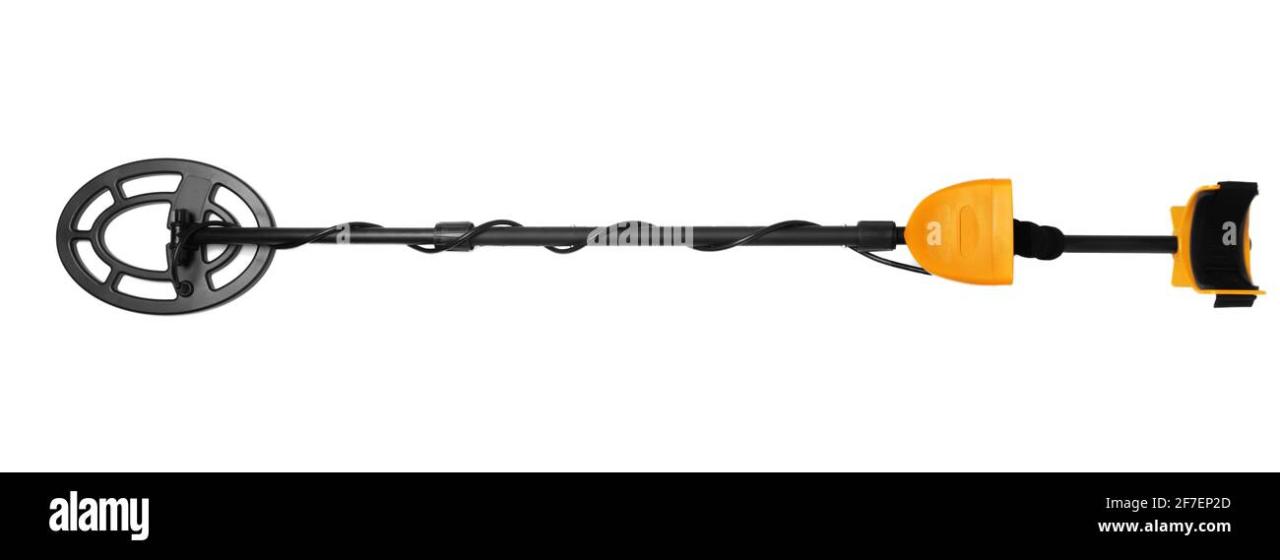

Illustrative Examples of White Metal Detectors

This section provides detailed descriptions of several white metal detectors, showcasing the range of available models and their respective features. The examples illustrate the diversity in size, weight, capabilities, and price points within the market. Understanding these differences is crucial for selecting the appropriate detector for a specific application.

Minelab GPZ 7000

The Minelab GPZ 7000 is a high-end gold prospecting detector renowned for its exceptional depth and sensitivity. It’s a relatively large and heavy unit, weighing approximately 3.5 kg (7.7 lbs), reflecting its powerful internal components. Its dimensions are substantial, designed for comfortable use during extended periods of prospecting. Key features include its advanced multi-frequency technology, offering unparalleled ground penetration, and its highly responsive coil, allowing for the detection of even small gold nuggets. The GPZ 7000 boasts a sophisticated user interface with various selectable search modes and settings to optimize performance in diverse ground conditions. The price range typically starts at around $8,000 USD.

Garrett AT Pro

The Garrett AT Pro represents a more affordable and versatile option suitable for various applications, including coin shooting, relic hunting, and general metal detecting. It’s considerably smaller and lighter than the GPZ 7000, weighing approximately 1.4 kg (3.1 lbs), making it easier to handle for extended periods. Its compact size and lightweight design make it highly portable. This detector is known for its excellent waterproof capabilities, allowing for use in wet conditions, and features such as ground balance, iron discrimination, and multiple search modes. The Garrett AT Pro offers a good balance between performance and affordability, with a price range typically between $600 and $800 USD.

Bounty Hunter Quick Silver

The Bounty Hunter Quick Silver is an entry-level metal detector, ideal for beginners or those seeking a simple, cost-effective solution. It’s lightweight and compact, making it highly portable and easy to use. The physical dimensions are relatively small, making it suitable for younger users or those with limited physical strength. Features are more basic than the previous examples, focusing on ease of use and affordability. It lacks some of the advanced features of higher-end models, but provides a reliable detection of common metallic objects. Its price typically falls within the $100-$200 USD range.

Fisher F75, Is white metal detectors still in business

The Fisher F75 is a highly regarded mid-range metal detector, often favored by experienced hobbyists and treasure hunters. It is characterized by its relatively robust construction and a balance between features and portability. The weight is moderate, around 2 kg (4.4 lbs), offering a good compromise between ease of use and detection performance. Its key features include advanced ground balancing capabilities, precise discrimination settings, and multiple frequency options. The F75 is known for its ability to accurately pinpoint targets and its performance in varied soil conditions. The price range typically sits between $800 and $1200 USD, placing it firmly in the mid-range category.