What degree is best for an epox business owner – What degree is best for an epoxy business owner? This question, central to entrepreneurial success in the burgeoning epoxy industry, demands careful consideration. The path to profitability isn’t solely paved with resin and hardeners; a solid educational foundation plays a crucial role. This exploration delves into various academic paths—from business administration and chemistry to engineering and entrepreneurship—evaluating their unique contributions to building and scaling a successful epoxy venture. We’ll weigh the pros and cons of each, helping you choose the educational trajectory best suited to your ambitions.

Choosing the right educational path depends heavily on your existing skills and career goals. Do you envision yourself primarily focused on the creative and technical aspects of epoxy production, or are you more interested in the business and management side? A strong understanding of chemistry and materials science is invaluable for product development and innovation, while business acumen is crucial for marketing, sales, and financial management. This guide aims to clarify the value proposition of each degree type, enabling you to make an informed decision that aligns with your personal strengths and long-term vision for your epoxy business.

Business Administration Degrees: What Degree Is Best For An Epox Business Owner

A business administration degree provides a comprehensive foundation in the principles and practices necessary to successfully manage and grow any business, including an epoxy business. This broad skillset encompasses crucial areas like finance, marketing, and operations, equipping entrepreneurs with the tools to navigate the complexities of running a profitable enterprise. Understanding these core business functions is paramount for long-term sustainability and growth within a competitive market.

Relevance of Business Administration to Epoxy Businesses

A business administration degree offers significant relevance to managing an epoxy business by providing a structured understanding of key functional areas. Financial management, for example, is crucial for tracking income and expenses, managing cash flow, and making informed investment decisions. Marketing principles help in developing effective strategies to reach target customers, build brand awareness, and ultimately drive sales. Operations management skills ensure efficient production processes, inventory control, and quality assurance, leading to improved productivity and customer satisfaction. These are all vital for the success of an epoxy business, regardless of size or specialization.

Application of Specific Business Administration Courses

Specific courses within a business administration program directly translate into practical applications for daily epoxy business operations. For instance, accounting courses provide the skills to manage financial records, create budgets, and understand profitability. Marketing management courses equip entrepreneurs with the knowledge to develop targeted marketing campaigns, utilizing digital marketing, social media, and potentially even print advertising to reach potential clients. Operations management courses cover topics like supply chain management, production planning, and quality control, all critical aspects of efficient epoxy production and delivery. Understanding these concepts allows for streamlined processes, cost optimization, and enhanced customer satisfaction.

General vs. Specialized Business Administration Degrees

While a general business administration degree offers a broad foundation, a specialized degree, such as one focusing on entrepreneurship or small business management, might offer more targeted skills for epoxy business owners. A general degree provides a wider range of knowledge, allowing for greater flexibility and adaptability to changing market conditions. A specialized degree, however, provides in-depth knowledge and skills directly applicable to starting and running a small business, potentially offering a faster path to operational efficiency. The best choice depends on the individual’s prior experience, learning style, and long-term goals. For example, an individual with prior business experience might benefit more from a general degree, while someone new to entrepreneurship might find a specialized program more beneficial.

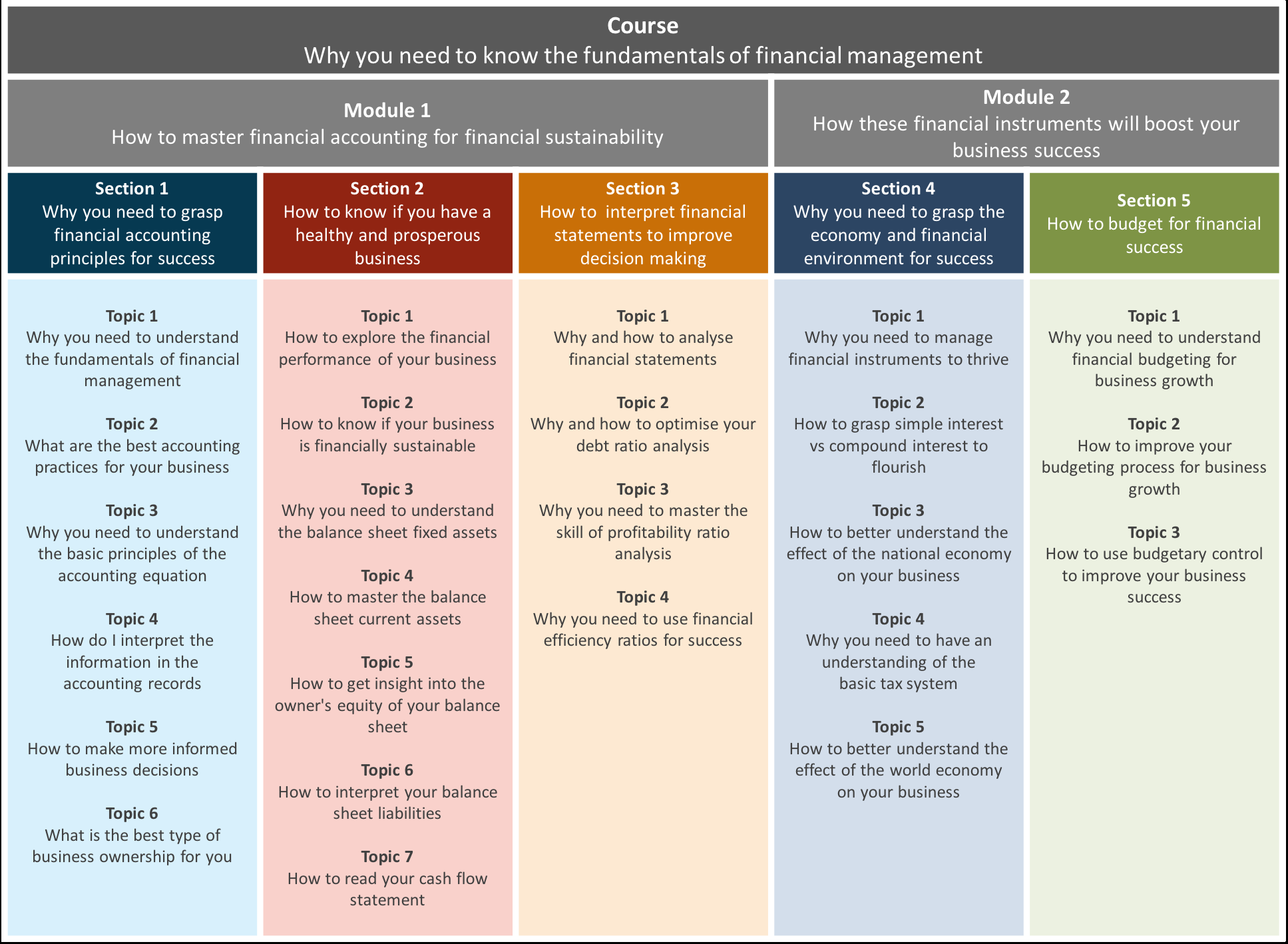

Hypothetical Curriculum for Epoxy Business Owners, What degree is best for an epox business owner

A tailored business administration program for epoxy business owners could incorporate modules such as: Financial Accounting for Small Businesses, focusing on accurate record-keeping and financial statement analysis; Marketing Strategies for Specialty Businesses, covering niche marketing techniques; Operations Management in Manufacturing, emphasizing production efficiency and quality control; Entrepreneurial Finance, covering securing funding and managing cash flow; Legal Aspects of Small Business Ownership, addressing liability and regulatory compliance; and Digital Marketing and Social Media Strategies, equipping entrepreneurs with the skills to leverage online platforms. This curriculum would provide a strong foundation in core business principles while addressing the specific needs and challenges of the epoxy industry.

Chemistry and Materials Science Degrees

A strong foundation in chemistry and materials science is invaluable for epoxy business owners. This knowledge base allows for the development of innovative products, optimization of existing formulations, and ensures safe handling practices, ultimately contributing to the success and competitiveness of the business. Understanding the underlying chemical principles governs the properties and performance of epoxy resins, leading to better product design and quality control.

The Role of Chemistry and Materials Science in Epoxy Product Development

A deep understanding of chemistry and materials science is crucial for developing new epoxy products and improving existing ones. Polymer chemistry provides the fundamental knowledge necessary to understand the synthesis, structure, and properties of epoxy resins and their curing agents (hardners). This understanding allows for the tailoring of epoxy formulations to achieve specific performance characteristics, such as increased strength, flexibility, heat resistance, or chemical resistance. For example, knowledge of reaction kinetics helps determine optimal curing conditions, while understanding the glass transition temperature (Tg) allows for the prediction of the epoxy’s performance at different temperatures. Furthermore, knowledge of material properties, such as viscosity, density, and thermal conductivity, is essential for optimizing processing and application methods.

Examples of Chemical Knowledge Leading to Epoxy Innovations

Knowledge in polymer chemistry, material properties, and chemical reactions directly translates into innovations within the epoxy industry. For instance, understanding the crosslinking mechanisms of epoxy resins allows for the development of high-performance epoxies with enhanced mechanical properties. By carefully selecting monomers and modifying the curing process, manufacturers can fine-tune the final product’s properties to meet specific application requirements. The development of water-based epoxy systems, for example, relies on a detailed understanding of the interactions between the epoxy resin, water, and emulsifiers, ensuring both performance and environmental compatibility. Another example is the creation of self-healing epoxies, which utilize microcapsules containing healing agents that are released upon crack formation, restoring the material’s integrity. This requires a sophisticated understanding of encapsulation technologies and chemical reactions.

Safety Regulations and Handling Procedures for Epoxy Resins

Understanding safety regulations and handling procedures related to epoxy resins and hardeners is paramount. Epoxy resins and hardeners often contain hazardous chemicals that can cause skin irritation, respiratory problems, or other health issues if not handled properly. A thorough understanding of relevant Occupational Safety and Health Administration (OSHA) regulations and Material Safety Data Sheets (MSDS) is critical. This includes proper personal protective equipment (PPE) usage, ventilation requirements, waste disposal procedures, and emergency response protocols. Failure to comply with these regulations can lead to serious consequences, including fines, legal liabilities, and workplace accidents. Implementing rigorous safety protocols is not just a legal requirement but also essential for protecting the health and well-being of employees and the environment.

Essential Chemistry and Materials Science Concepts for Epoxy Business Owners

A comprehensive understanding of the following concepts is vital for success in the epoxy business:

| Concept | Description |

|---|---|

| Polymer Chemistry | Understanding polymerization mechanisms, types of polymers (thermosets, thermoplastics), and the relationship between polymer structure and properties. |

| Material Properties | Knowledge of mechanical properties (tensile strength, modulus, hardness), thermal properties (glass transition temperature, thermal expansion), and chemical resistance. |

| Chemical Reactions | Understanding the chemistry of epoxy curing reactions, including kinetics, thermodynamics, and the influence of catalysts and accelerators. |

| Rheology | Understanding the flow behavior of epoxy resins and how it affects processing and application methods. |

| Surface Chemistry | Knowledge of surface interactions and adhesion mechanisms is crucial for ensuring proper bonding and coating performance. |

| Spectroscopic Techniques | Familiarity with techniques like FTIR, NMR, and DSC for characterizing epoxy resins and cured products. |

Engineering Degrees (Chemical, Mechanical)

An engineering background, particularly in chemical or mechanical engineering, offers significant advantages for epoxy business owners. The rigorous training in problem-solving, process optimization, and design thinking directly translates to improved efficiency, higher quality products, and increased profitability within the epoxy manufacturing and application sectors. This expertise is crucial in navigating the complexities of epoxy formulation, production, and application.

Engineering principles are deeply embedded in every stage of an epoxy business. From the initial formulation and synthesis of the epoxy resin and hardener, through the mixing and curing processes, to the final application and quality control, a strong engineering foundation proves invaluable. Understanding process control ensures consistent product quality, while design optimization leads to more efficient manufacturing processes and reduced waste. Quality control, guided by engineering principles, minimizes defects and ensures the final product meets stringent specifications.

Application of Engineering Principles in Epoxy Manufacturing

Process control, a core concept in chemical and mechanical engineering, is paramount in epoxy manufacturing. Maintaining precise temperature, pressure, and mixing ratios is critical to achieving the desired properties of the cured epoxy. Deviations from these parameters can lead to variations in viscosity, curing time, and mechanical strength, directly impacting product quality and consistency. For example, precise temperature control during the curing process is crucial to prevent defects like porosity or incomplete curing. Statistical Process Control (SPC) methods, commonly taught in engineering programs, can be used to monitor and control these variables, ensuring consistent output. Similarly, quality control techniques, including material testing and analysis, are crucial for ensuring the final product meets the specified standards. Mechanical engineers contribute by designing and optimizing the equipment used in these processes.

Chemical Engineering vs. Mechanical Engineering in Epoxy Businesses

Chemical engineering focuses on the chemical processes involved in epoxy formulation, synthesis, and modification. A chemical engineer is well-equipped to understand the chemical reactions, optimize the formulation process, and develop new epoxy formulations with specific properties. They are vital in ensuring the consistent quality and performance of the epoxy resin. In contrast, mechanical engineering focuses on the design, manufacturing, and operation of the equipment used in the epoxy manufacturing process. Mechanical engineers design and improve mixing tanks, dispensing systems, curing ovens, and other critical equipment, ensuring efficient and reliable production. They play a key role in optimizing production lines and improving overall manufacturing efficiency.

Comparison of Chemical and Mechanical Engineering Degrees for Epoxy Business Ownership

| Feature | Chemical Engineering | Mechanical Engineering |

|---|---|---|

| Advantages | Deep understanding of epoxy chemistry, formulation optimization, quality control of the resin itself. | Expertise in equipment design, process optimization, and improving manufacturing efficiency. |

| Disadvantages | May lack expertise in equipment design and large-scale production processes. | May have limited understanding of the intricate chemical reactions involved in epoxy formulation. |

| Best Suited For | Developing new epoxy formulations, ensuring product quality, and overseeing the chemical aspects of production. | Optimizing manufacturing processes, designing and maintaining equipment, and improving production efficiency. |

| Relevance to Business | High – crucial for product development and quality control. | High – crucial for efficient and cost-effective production. |

Entrepreneurship and Small Business Management

An entrepreneurship degree offers epoxy business owners a significant advantage, providing a structured framework for navigating the complexities of business ownership. This goes beyond the technical aspects of epoxy resin work and equips individuals with the crucial business acumen needed to build a sustainable and profitable enterprise. A strong understanding of business principles is vital for long-term success in any industry, and the epoxy market is no exception.

An entrepreneurship curriculum typically covers vital areas such as business planning, fundraising, and growth strategies. These skills are directly applicable to the epoxy business, enabling owners to effectively plan for production, marketing, and expansion. A well-structured business plan, for instance, helps secure funding, guides operational decisions, and provides a roadmap for future growth. Furthermore, an understanding of fundraising techniques allows entrepreneurs to access capital needed for equipment, marketing, and hiring, crucial for scaling the business.

Business Planning and Fundraising for Epoxy Businesses

A comprehensive business plan for an epoxy business should include a thorough market analysis identifying target customer segments (e.g., DIY enthusiasts, interior designers, artists), analyzing competitor offerings, and defining a unique selling proposition (USP). This analysis informs pricing strategies, marketing campaigns, and product development decisions. Financial projections, including startup costs, revenue forecasts, and profitability analysis, are essential for securing funding from investors or lenders. Successful fundraising often involves crafting a compelling pitch deck that highlights the market opportunity, the business model, and the management team’s capabilities. Securing funding might involve approaching angel investors, venture capitalists, or applying for small business loans. Examples of successful fundraising strategies include showcasing a strong track record of sales, demonstrating a clear path to profitability, and presenting a well-defined exit strategy.

Growth Strategies and Examples of Success

Effective growth strategies for an epoxy business might involve expanding product lines (e.g., offering custom epoxy creations, workshops, or online courses), exploring new distribution channels (e.g., partnering with retailers, establishing an e-commerce store), or targeting new customer segments. Many successful entrepreneurs in related industries leveraged their business knowledge to build thriving enterprises. For example, consider the success of small-batch manufacturers who focused on high-quality, handcrafted goods, similar to the niche market potential of bespoke epoxy creations. Their success often stemmed from strong brand building, effective marketing, and a deep understanding of their target customer base. Another example might be a craft business owner who successfully scaled their operation by leveraging social media marketing and online sales channels, a strategy directly transferable to the epoxy business.

Developing a Comprehensive Business Plan for the Epoxy Industry

The process of developing a business plan for an epoxy business starts with market research. This involves identifying the target audience, understanding their needs and preferences, and analyzing the competitive landscape. The next step is to define the business model, outlining the products or services offered, the pricing strategy, and the sales channels. A detailed financial plan, including startup costs, operating expenses, and revenue projections, is crucial for securing funding and making informed business decisions. Finally, the business plan should include a marketing and sales strategy, outlining how the business will reach its target customers and generate sales. This plan should be dynamic and adaptable, allowing for adjustments based on market feedback and business performance.

Launching and Scaling an Epoxy Business: A Step-by-Step Flowchart

The flowchart begins with *Market Research and Business Plan Development*. This is followed by *Securing Funding and Resources*, encompassing securing capital and acquiring necessary equipment. Next is *Product Development and Production*, involving refining techniques and establishing a production process. *Marketing and Sales Strategy Implementation* follows, including building an online presence and engaging with potential customers. The next step is *Sales and Order Fulfillment*, efficiently managing orders and ensuring customer satisfaction. *Business Growth and Expansion* involves scaling production, exploring new markets, and potentially hiring additional staff. Finally, *Continuous Improvement and Adaptation* ensures ongoing business success by adapting to market changes and customer feedback. Each step is visually represented by a rectangle, with arrows indicating the sequential flow.

Vocational Training and Certifications

For aspiring epoxy business owners, a formal degree isn’t always the most direct path to success. Hands-on experience and industry-recognized certifications can provide a crucial competitive edge, offering practical skills and demonstrating a commitment to safety and quality. This approach often proves more cost-effective and time-efficient than pursuing a four-year degree program, particularly when combined with entrepreneurial acumen.

Vocational training and certifications offer practical, specialized skills directly applicable to the epoxy industry. These programs focus on hands-on application techniques, safety protocols, and industry best practices, often leading to faster entry into the market and quicker return on investment compared to traditional degree programs. The value of these credentials lies in their immediate applicability, enhancing a business owner’s credibility and providing demonstrable expertise to clients.

Types of Certifications and Training Programs

Several avenues exist for obtaining vocational training and certifications in epoxy application and safety. These range from short-term workshops focusing on specific epoxy systems to comprehensive programs covering various aspects of the trade. Industry-specific safety certifications are also crucial, demonstrating a commitment to safe working practices and compliance with relevant regulations. Examples include certifications from organizations such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) for handling hazardous materials and working with flammable substances. Specialized training courses often cover advanced techniques, such as epoxy flooring installation, automotive coatings, or specialized industrial applications. Many manufacturers of epoxy resins also provide training programs on their specific product lines.

Cost-Effectiveness and Time Commitment

Compared to the substantial time and financial investment required for a four-year degree, vocational training programs offer a significantly more cost-effective and time-efficient alternative. Short-term courses can be completed in a few days or weeks, providing immediate skill enhancement. The cost of these courses is typically far lower than tuition fees for a full degree program. However, the depth of knowledge gained may be less extensive. The choice between vocational training and a formal degree depends heavily on the individual’s learning style, career goals, and financial resources. An entrepreneur focused on rapid business growth might prioritize hands-on training to quickly gain practical skills, while someone aiming for a more research-oriented role might benefit more from a formal degree in a related field.

Vocational Training Options

The following table Artikels various vocational training options, their duration, and the skills acquired. Note that durations can vary depending on the provider and course intensity.

| Training Program | Duration | Skills Acquired |

|---|---|---|

| Basic Epoxy Application Workshop | 1-3 days | Surface preparation, mixing ratios, application techniques for basic epoxy coatings. |

| Advanced Epoxy Flooring Installation Course | 1-2 weeks | Advanced mixing techniques, specialized tools, installation of various epoxy flooring systems, troubleshooting. |

| Epoxy Resin and Hardener Safety Training | 1-2 days | Handling hazardous materials, personal protective equipment (PPE) use, emergency procedures, waste disposal. |

| Manufacturer-Specific Epoxy Training | Varies | Product-specific application techniques, troubleshooting, and best practices for a particular epoxy system. |