What is the best DTF printer for small business? This question plagues many entrepreneurs seeking to elevate their branding and product offerings with vibrant, high-quality custom prints. The answer, however, isn’t a simple one-size-fits-all solution. Choosing the right Direct-to-Film (DTF) printer hinges on several crucial factors, from your business type and budget to the specific demands of your printing needs. Understanding these variables is key to making an informed decision that maximizes your return on investment and streamlines your workflow.

This guide delves into the world of DTF printing technology, exploring its advantages and disadvantages compared to other methods. We’ll dissect the key features to consider when selecting a DTF printer tailored to your small business, examining factors like print size, speed, ink capacity, and software compatibility. Furthermore, we’ll navigate the complexities of budgeting, maintenance, and workflow integration to help you choose the perfect DTF printer for your unique circumstances. We’ll even explore real-world examples of successful small businesses leveraging DTF printing to achieve remarkable growth.

Defining “Best” for Small Businesses

Selecting the “best” DTF printer for a small business isn’t a simple matter of picking the cheapest or fastest option. The ideal printer depends heavily on the specific needs and priorities of the business. Several key factors influence this decision, making it crucial to understand your individual requirements before making a purchase.

Small businesses prioritize different aspects of a DTF printer based on their operational needs and budget constraints. Cost is always a significant factor, especially for startups with limited capital. Print quality is paramount for businesses focusing on high-end products or branding, while speed is crucial for those with high-volume print demands. Reliability, minimizing downtime and maintenance, is vital for all businesses to maintain productivity. Finally, ease of use is important to ensure efficient operation, regardless of technical expertise within the team.

Varied Needs Across Small Business Types

The ideal DTF printer varies significantly depending on the type of small business. A home-office-based graphic designer will have different needs than a busy retail store producing custom t-shirts or a restaurant needing to print menu updates quickly. A home office might prioritize ease of use and lower print volume, while a retail store might prioritize speed and durability of prints. A restaurant may require a balance of speed and ease of use to ensure efficient menu updates.

Printer Feature Comparison for Different Business Types

The following table compares the importance of key DTF printer features across different small business types:

| Feature | Home Office | Retail Store | Restaurant |

|---|---|---|---|

| Print Speed | Low Importance | High Importance | Medium Importance |

| Print Quality | High Importance | High Importance | Medium Importance |

| Cost | High Importance | Medium Importance | Medium Importance |

| Ease of Use | High Importance | Medium Importance | High Importance |

| Reliability | Medium Importance | High Importance | Medium Importance |

| Print Volume Capacity | Low Importance | High Importance | Low Importance |

Direct-to-Film (DTF) Printer Technology Explained

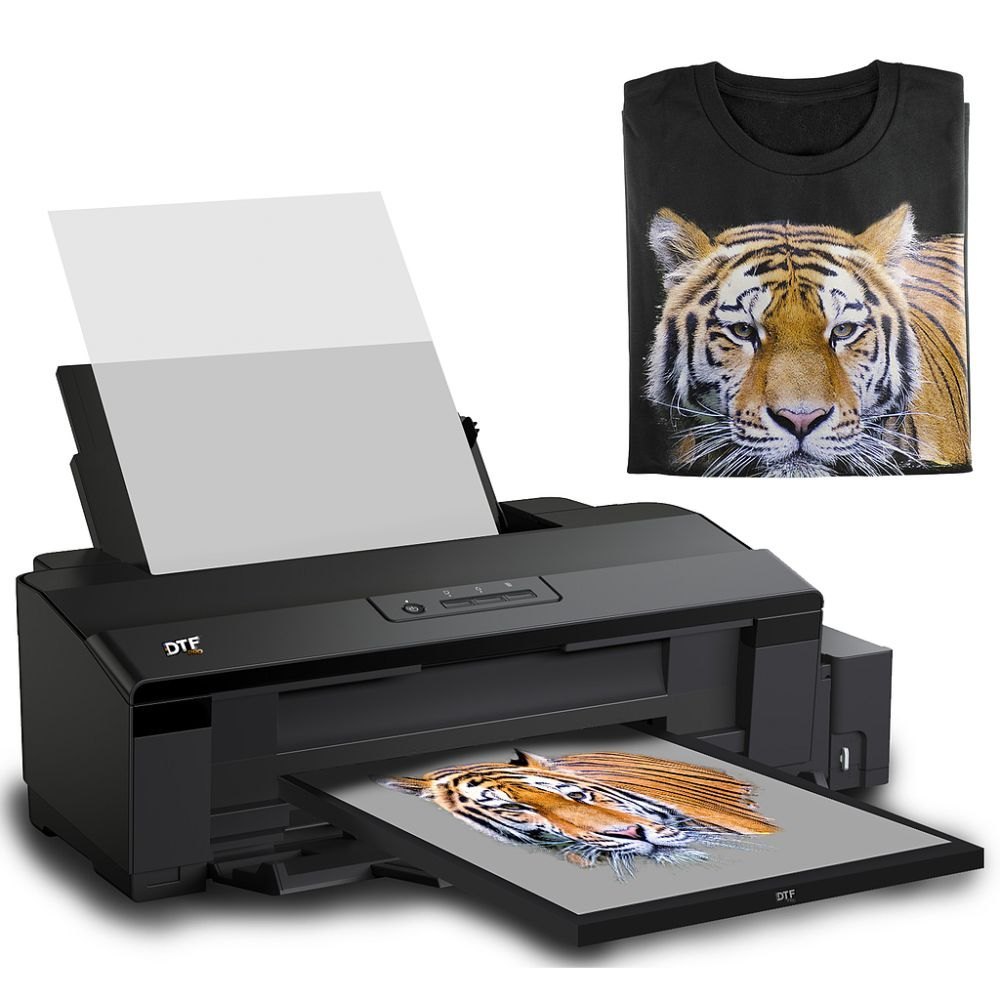

Direct-to-film (DTF) printing is a relatively new digital printing method gaining popularity for its versatility and cost-effectiveness, particularly for small businesses. It offers a compelling alternative to traditional methods like screen printing and direct-to-garment (DTG) printing, boasting a unique approach to transferring designs onto various substrates.

DTF printing involves first printing a design onto a special film using a specialized printer. This film is coated with a heat-activated adhesive. The printer utilizes specialized inks, typically including white ink for vibrant colors on dark fabrics, and CMYK inks to create the full-color design. After printing, the film is then coated with a powder adhesive, often a polyurethane-based powder, which is cured using a heat press. This process bonds the ink to the film, creating a durable and flexible transfer. Finally, the design is transferred from the film to the garment or substrate using a heat press, fusing the design permanently. The entire process allows for high-resolution, vibrant prints on a wide range of materials.

DTF Printing Process Details

The DTF process comprises several key stages. First, a digital design is created and sent to the DTF printer. The printer uses specialized inks, typically a combination of white ink and CMYK (cyan, magenta, yellow, key/black) inks. The white ink acts as a base layer, crucial for ensuring vibrant colors on dark-colored fabrics. The inks are then printed onto a special PET film. Following the printing process, a fine layer of hot-melt adhesive powder is applied to the printed film. This powder acts as the binding agent that adheres the print to the garment. The powder-coated film then passes through a curing oven, which melts and sets the adhesive. Finally, the cured film is pressed onto the substrate using a heat press, transferring the design and fusing it to the material.

Advantages and Disadvantages of DTF Printing

DTF printing offers several advantages over other printing methods. Its ability to print on a wide variety of fabrics and materials, including cotton, polyester, nylon, and blends, makes it highly versatile. The high-resolution prints produced are vibrant and durable, rivaling the quality of screen printing. Furthermore, DTF printing is relatively cost-effective for smaller print runs compared to screen printing, which involves higher setup costs. However, DTF printing requires a higher initial investment in equipment compared to DTG printing. The additional step of transferring the print also adds to the overall production time, potentially impacting efficiency for very large orders. The longevity of the prints on certain fabrics may also be a factor to consider, as compared to DTG printing.

DTF Printer Maintenance and Costs

Maintaining a DTF printer involves regular cleaning of the print heads to prevent clogging, which is crucial for maintaining print quality. Ink cartridges need to be replaced as they run out, and the curing oven may require periodic maintenance. The costs associated with maintenance vary depending on usage frequency and the printer model. Factors influencing the overall cost include ink costs, cleaning solution costs, and potential repair or replacement of components. It’s essential to factor in these costs when assessing the overall operational expenses of a DTF printing business. For example, a high-volume business might see higher maintenance costs compared to a small business with lower print volumes. Preventive maintenance, such as regular cleaning and inspection, can help mitigate unexpected breakdowns and reduce long-term costs.

Top DTF Printer Features for Small Businesses

Choosing the right DTF printer for a small business requires careful consideration of several key features. The ideal printer will balance cost-effectiveness with the production needs of the business, ensuring both efficiency and profitability. This section Artikels the most important features to look for, categorized by their level of importance.

Essential DTF Printer Features for Small Businesses

The following features are crucial for any small business looking to implement DTF printing effectively. These features directly impact the efficiency and quality of production, influencing both output and profitability.

- Print Size: A larger print area allows for the creation of larger designs without the need for multiple prints and piecing, significantly improving efficiency. A print bed of at least 13″ x 17″ is generally recommended for versatility, allowing for the production of a wide range of apparel and other items. Smaller print sizes limit versatility and can lead to increased production time.

- Print Speed: Faster print speeds translate to higher output and quicker turnaround times, crucial for meeting deadlines and satisfying customer demands. Look for printers with print speeds measured in square meters per hour (m²/hr) or square feet per hour (ft²/hr), aiming for a speed that aligns with your anticipated order volume. A slower printer might be suitable for very small businesses with low order volumes, while a faster printer is necessary for higher-volume operations.

- Reliable Ink System: A robust and efficient ink system is vital for consistent print quality and minimal downtime. Features such as high-capacity ink cartridges, easy ink refilling mechanisms, and automatic ink level monitoring significantly reduce interruptions in the printing process. Look for printers that utilize CMYK inks plus white ink for printing on dark garments and other substrates.

- Software Compatibility: Seamless integration with design software is essential for efficient workflow. Ensure the printer is compatible with industry-standard design software like Adobe Photoshop and Illustrator, along with RIP software designed for optimal DTF printing. Compatibility issues can create bottlenecks and hinder productivity.

Desirable DTF Printer Features for Small Businesses

While not strictly essential, these features can significantly enhance productivity and the overall user experience, contributing to a more efficient and streamlined workflow.

- Automated Features: Features like automatic printhead cleaning and maintenance routines reduce manual intervention and minimize the risk of human error. This translates to less downtime and consistent print quality. Examples include automatic capping and purging of the printheads.

- Intuitive Control Panel: A user-friendly control panel simplifies operation and reduces the learning curve, allowing for quick and easy adjustments to print settings. This is particularly important for businesses with limited technical expertise.

- Durable Build Quality: A robust and durable printer construction ensures longevity and minimizes the risk of breakdowns, reducing downtime and repair costs. Consider printers with sturdy frames and high-quality components.

Optional DTF Printer Features for Small Businesses

These features are beneficial but not necessarily crucial for all small businesses. Their value depends on the specific needs and priorities of the business.

- Pre-treatment System Integration: Some DTF printers offer integrated pre-treatment systems, simplifying the workflow and ensuring consistent pre-treatment application. While convenient, this feature adds to the initial investment cost.

- Advanced Color Management: Advanced color management tools provide finer control over color accuracy and consistency. This is particularly beneficial for businesses working with intricate designs or requiring precise color matching.

Budget Considerations for DTF Printers: What Is The Best Dtf Printer For Small Business

Investing in a DTF printer for your small business requires careful consideration of the financial implications. The initial purchase price is just one element of the overall cost; ongoing expenses like ink, maintenance, and replacement parts significantly impact the long-term profitability of your investment. Understanding these costs and projecting your return on investment is crucial for making an informed decision.

The price range for DTF printers suitable for small businesses is quite broad, depending on print size, speed, and features. Entry-level models can start around $3,000, while more advanced printers with larger print beds and faster print speeds can cost upwards of $15,000 or more. Factors influencing price include print head technology, print resolution, and the level of automation included in the machine.

Total Cost of Ownership (TCO) for DTF Printers

Calculating the total cost of ownership is essential for accurately assessing the financial viability of a DTF printer. This goes beyond the initial purchase price and encompasses all associated expenses over the printer’s lifespan. These costs include ink, maintenance (including cleaning supplies and potential repairs), replacement parts (like print heads), and electricity consumption. For example, a budget-friendly printer might have lower initial costs, but higher ink consumption and more frequent maintenance could offset these savings in the long run. Conversely, a higher-priced model might offer lower running costs due to better ink efficiency and durability. Consider factors like print volume – a business printing hundreds of shirts daily will experience higher ink and maintenance costs than one printing only a few dozen.

Return on Investment (ROI) Calculation for DTF Printers

Calculating the ROI for a DTF printer helps determine the profitability of your investment. A simple ROI calculation involves comparing the net profit generated by the printer against its total cost. To illustrate, let’s consider a small business owner who invests $5,000 in a DTF printer. Over a year, they generate $15,000 in revenue from DTF printed products, with associated costs (excluding the printer) of $5,000. The net profit is therefore $10,000 ($15,000 – $5,000). The ROI is calculated as follows:

ROI = (Net Profit / Total Investment) x 100%

ROI = ($10,000 / $5,000) x 100% = 200%

This indicates a 200% return on investment within one year. However, this is a simplified example. A more comprehensive calculation should incorporate the depreciation of the printer over its useful life, along with the ongoing costs of ink, maintenance, and other supplies. Accurate forecasting of print volume and pricing strategies are also crucial for a realistic ROI projection. A detailed financial model, incorporating these factors, will provide a more accurate and reliable prediction.

Software and Workflow Integration

Seamless software integration and a streamlined workflow are crucial for maximizing the efficiency and profitability of a DTF printer in a small business. The right software can significantly reduce production time, minimize errors, and improve overall output quality. Choosing compatible software and optimizing your workflow are key factors in achieving a successful DTF printing operation.

The effectiveness of a DTF printer hinges heavily on the design software and printing process. A well-integrated system ensures smooth transitions between design, printing, and transfer, minimizing bottlenecks and maximizing productivity. This section explores the software options and workflow processes involved in achieving this seamless integration.

Design Software Compatibility

DTF printers are compatible with a wide range of design software, catering to various skill levels and design needs. Popular choices include Adobe Photoshop, Adobe Illustrator, CorelDRAW, and Affinity Designer. These programs allow for the creation of intricate designs, precise vector graphics, and high-resolution raster images, all essential for high-quality DTF prints. The ability to export designs in common file formats like PNG, TIFF, and PDF ensures compatibility with most DTF printer drivers. Choosing the right software depends on the designer’s familiarity and the complexity of the designs being created. For instance, a business specializing in simple, text-based designs might find a simpler program like Affinity Designer sufficient, while one creating complex, multi-layered images might prefer the advanced features of Adobe Photoshop.

DTF Printing Workflow

The typical DTF printing workflow involves several key steps: design creation, file preparation, printing, powder application, curing, and finally, transferring the printed image onto the garment. First, the design is created in chosen software, ensuring color accuracy and resolution. The file is then exported in a suitable format for the DTF printer. The printer then applies the ink to a special film, after which a heat-activated adhesive powder is applied to the printed ink. The film is then cured using a heat press to bond the ink and powder. Finally, the printed film is heat-pressed onto the garment, transferring the design. This entire process requires careful attention to detail at each stage to ensure a high-quality, long-lasting print. A well-defined workflow, possibly using project management software, is crucial for managing orders and tracking progress.

Integrating DTF Printing into Existing Workflows

Integrating a DTF printer into an existing small business workflow requires careful planning and consideration. For businesses already using print-on-demand services, DTF printing can offer greater control over quality and faster turnaround times. The integration might involve creating a dedicated workspace for the DTF printer and associated equipment. It may also involve training employees on the use of the printer and the associated software. For example, a small apparel business could integrate DTF printing into its existing workflow by assigning a dedicated employee to handle the DTF printing process, while others focus on design, order fulfillment, and customer service. A business using an existing order management system can adapt it to include the DTF printing stage, allowing for better tracking of production and inventory. Similarly, a business might integrate DTF printing into their existing e-commerce platform, allowing customers to customize their orders with DTF prints.

Maintenance and Troubleshooting

Keeping your DTF printer in optimal condition is crucial for consistent, high-quality prints and minimizing downtime. Regular maintenance prevents costly repairs and ensures the longevity of your investment. Understanding common issues and troubleshooting techniques will empower you to address problems quickly and efficiently.

Regular maintenance and proactive troubleshooting are essential for maximizing the lifespan and productivity of your DTF printer. Neglecting these aspects can lead to costly repairs, production delays, and ultimately, impact your business’s bottom line. This section details common maintenance tasks and provides a structured approach to troubleshooting frequent problems.

DTF Printer Maintenance Tasks, What is the best dtf printer for small business

Regular cleaning and ink refills are vital for maintaining print quality and preventing nozzle clogging. Ignoring these tasks can lead to faded colors, inconsistent prints, and ultimately, printer malfunctions. A proactive maintenance schedule will save you time and money in the long run.

- Daily Cleaning: Before and after each printing session, wipe the printhead with a lint-free cloth dampened with distilled water. This removes any dried ink that might clog the nozzles.

- Weekly Cleaning: Perform a deeper cleaning using the printer’s built-in cleaning function (if available). This usually involves a more thorough cleaning cycle that flushes the ink lines and removes any accumulated debris.

- Monthly Maintenance: Inspect the printhead for any signs of damage or wear. Replace the printhead if necessary, following the manufacturer’s instructions. Check all ink lines for blockages and clear them if needed.

- Ink Refills: Regularly monitor ink levels and refill cartridges as needed. Use only high-quality inks recommended by the manufacturer to avoid damaging the printer or compromising print quality. Proper ink management prevents ink starvation and maintains color consistency.

Troubleshooting Common DTF Printer Problems

Several issues can arise with DTF printers. Understanding the symptoms and implementing appropriate troubleshooting steps will minimize downtime and ensure smooth operation. This section Artikels common problems and their solutions.

- Nozzle Clogging: This often manifests as missing colors, streaks, or faded prints. Troubleshooting involves performing a deep cleaning cycle, followed by a printhead alignment. If the problem persists, consider replacing the printhead.

- Ink Smearing or Bleeding: This indicates a problem with the ink viscosity or the printhead temperature. Check the ink levels and ensure you are using the correct type of ink. Adjust the printhead temperature according to the manufacturer’s guidelines.

- Printhead Alignment Issues: Misaligned printheads result in blurry or misaligned prints. Use the printer’s built-in alignment function to correct the alignment. If the problem continues, contact the manufacturer’s technical support.

- Paper Feed Problems: This can manifest as jammed paper or uneven feeding. Ensure the paper is properly loaded and that the paper path is clear of obstructions. Check the paper guides and adjust them if necessary.

DTF Printer Troubleshooting Flowchart

A systematic approach to troubleshooting is crucial for efficient problem-solving. The following flowchart illustrates a logical sequence for addressing common DTF printer issues. This structured approach minimizes guesswork and ensures a timely resolution.

(Note: A visual flowchart would be included here. It would start with a “Problem Detected?” Yes/No branch. A “Yes” branch would lead to a series of questions regarding the specific problem (e.g., poor print quality, paper jam, etc.). Each question would lead to specific troubleshooting steps, such as checking ink levels, cleaning the printhead, or checking paper feed. The flowchart would ultimately lead to a solution or a recommendation to contact technical support.)

Case Studies of Small Businesses Using DTF Printers

Direct-to-film (DTF) printing has revolutionized the way small businesses approach custom apparel and promotional item creation. Its versatility, affordability, and high-quality output make it an attractive option for entrepreneurs seeking to expand their product offerings and increase profit margins. The following case studies illustrate the successful implementation of DTF printing across various small business sectors.

Apparel Decoration in a Boutique Clothing Store

A small, independent boutique specializing in women’s clothing saw a significant increase in sales and brand recognition after integrating a DTF printer into their workflow. Previously, they relied on external screen printing services, which resulted in high costs, longer turnaround times, and limited design flexibility. By purchasing a DTF printer, they gained control over the entire production process, enabling them to offer personalized apparel with intricate designs and quicker delivery times. This allowed them to fulfill custom orders efficiently, cater to trending styles with speed, and introduce limited-edition items that resonated strongly with their customer base. The ability to print on a wider variety of fabrics, including delicate materials, also expanded their product range. The improved efficiency and reduced outsourcing costs directly translated into increased profitability.

Personalized Gifts and Promotional Items for an Event Planning Company

An event planning company experienced a transformation in their offerings by incorporating DTF printing. They previously relied on generic promotional items, limiting their ability to create memorable, personalized experiences for clients. The DTF printer enabled them to produce custom-designed merchandise, such as t-shirts, tote bags, and keychains, with high-resolution logos and event-specific designs. This allowed them to offer unique and branded souvenirs for attendees, enhancing client satisfaction and creating additional revenue streams. The ability to print small batches quickly and efficiently also allowed them to cater to last-minute requests and accommodate changes in event details without incurring significant extra costs. This improved responsiveness and flexibility contributed to the company’s growing reputation for delivering exceptional service.

Custom Merchandise for a Brewery

A craft brewery leveraged DTF printing to create highly personalized and engaging merchandise for their customers. They used the technology to print vibrant designs on t-shirts, hats, and even beer coasters, boosting brand loyalty and offering unique souvenirs for visitors to their taproom. The speed and efficiency of DTF printing allowed them to easily update designs based on seasonal promotions or limited-edition brews, keeping their merchandise fresh and relevant. This resulted in increased sales of merchandise and a stronger connection with their customer base, who appreciated the high-quality, personalized items. The brewery also reported reduced inventory costs due to the ability to print on demand, minimizing the risk of holding unsold stock.

Future Trends in DTF Printing Technology

The Direct-to-Film (DTF) printing market is dynamic, constantly evolving to meet the growing demands of businesses seeking efficient and high-quality textile printing solutions. Several key trends are shaping the future of DTF technology, promising increased speed, enhanced versatility, and improved cost-effectiveness for small businesses. These advancements will significantly impact the accessibility and profitability of DTF printing for entrepreneurs.

Emerging trends point towards a future where DTF printing becomes even more streamlined and accessible, fueled by innovations in ink technology, printer hardware, and software integration. This will lead to faster production times, broader material compatibility, and ultimately, greater return on investment for small businesses utilizing this technology.

New Ink Types and Formulations

Advancements in ink chemistry are driving significant improvements in DTF printing. The development of eco-friendly, water-based inks is a major focus, addressing environmental concerns and reducing the overall carbon footprint of the printing process. These inks often offer improved vibrancy and durability compared to their predecessors, leading to higher-quality prints with longer lifespans. Furthermore, research into inks with enhanced elasticity and flexibility promises to expand the range of fabrics suitable for DTF printing, including more delicate and stretchy materials. For example, the introduction of inks specifically designed for sportswear fabrics could significantly broaden the market reach for small businesses specializing in athletic apparel customization.

Improved Print Speeds and Automation

Increased print speeds are a crucial factor for small businesses seeking to maximize productivity and meet tight deadlines. Manufacturers are investing heavily in optimizing printhead technology and improving the overall efficiency of DTF printers. This includes the development of faster printheads with greater nozzle density, allowing for quicker print times without compromising print quality. Moreover, the integration of automated systems, such as automated feeding and unwinding mechanisms, is reducing manual handling time and improving overall workflow efficiency. A small business owner might see a 20% increase in daily output with the adoption of a printer featuring such automation, translating directly into increased revenue and order fulfillment capacity.

Enhanced Software Integration and Workflow Optimization

Software plays a vital role in streamlining the DTF printing process. The development of user-friendly design software with seamless integration with DTF printers is crucial for improving efficiency. This includes software that facilitates pre-press preparation, color management, and print job scheduling. Cloud-based solutions allow for remote monitoring and control of printers, providing valuable insights into production data and enabling proactive maintenance. Furthermore, the integration of Artificial Intelligence (AI) in software could automate certain aspects of the workflow, such as automatic color correction and print job optimization, leading to improved accuracy and reduced waste.

Timeline of Projected Advancements

| Year | Projected Advancement | Impact on Small Businesses |

|---|---|---|

| 2024-2025 | Widespread adoption of eco-friendly, water-based inks; Increased print speeds (15-20% faster than current models). | Reduced environmental impact; increased order fulfillment capacity; improved profitability. |

| 2026-2027 | Integration of AI-powered software for automated color correction and print job optimization; More advanced automation features in printers (e.g., automatic weeding). | Reduced labor costs; improved print accuracy; less material waste. |

| 2028-2030 | Development of inks compatible with a wider range of fabrics, including specialty materials; Increased printhead resolution for finer detail and sharper images. | Expansion into new markets; ability to offer more sophisticated and high-quality prints. |